-

API 609 Butterfly valve

Butterfly valve, also commonly known as a flap valve, is a type of regulating valve that is widely used in various industries for controlling the flow of fluids. It consists of several key components, including a valve body, valve stem, butterfly plate, and sealing ring. These components work together to ensure efficient and precise operation of the valve.

-

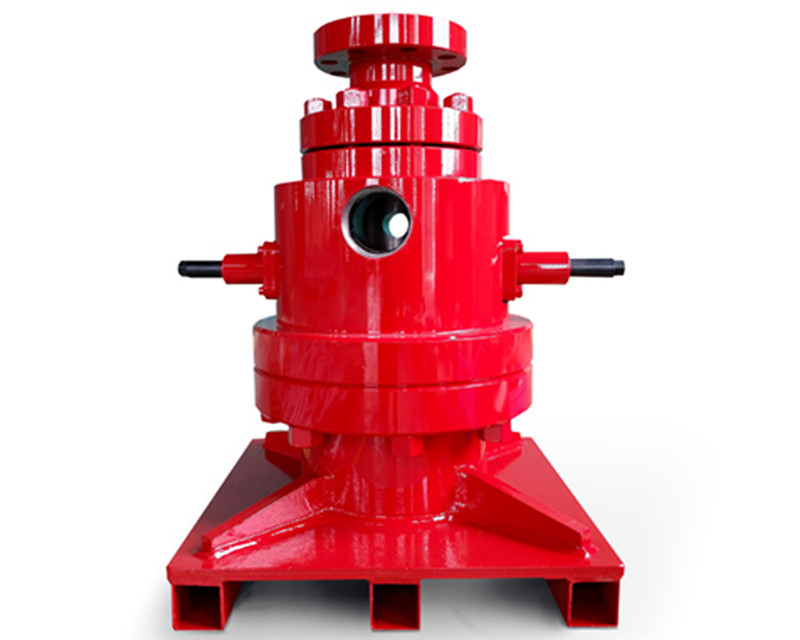

API 16A sucker-rod Blowout preventer

Mainly used in artificial lifting oil production systems to effectively control the internal pressure of the wellbore and prevent blowout.

The sucker rod blowout preventer equipped with special rams can clamp the pipe string, seal the annular space between the pipe string and the wellhead, and also withstand the weight and rotational torque of the downhole pipe string. -

API 6A Adapter Flange&Blind Flange&Companion Flange&weld neck flange

Flange are mainly used for connect the wellhead equipment . Christmas tree and other well control equipment .A wide variety of types including flange spool thread flange and Blank Flange etc.

-

API 6A Wellhead manual & hydraulic Choke Valves

Choke valve is a main component of Christmas tree and designed to control production output of the oil well, the materials of the body and components of choke valve are completely in conformity with API 6A and NACE MR-0175 Standard Specifications, and it is widely used for onshore and offshore petroleum drilling. The throttle valve is mainly used to adjust the flow and pressure of the manifold system; There are two types of flow control valves: fixed and adjustable. Adjustable throttle valves are divided into needle type, inner cage sleeve type, outer cage sleeve type and orifice plate type according to the structure; According to the operation mode, it can be divided into manual and hydraulic two. The end connection of choke Valve is thread or Flange, connected by non or flange. Choke valve falls into: positive choke valve, needle choke valve, adjustable choke valve, cage choke valve and orifice choke valve, etc.

-

Coiled Tubing

stripper assembly Coiled Tubing BOP is a key part in well logging devices, and it is mainly used to control pressure at the wellhead during the process of well logging, well workover and production test, so as to effectively avoid blowout and to realize safe production.A Coiled Tubing BOP is composed of quad ram BOP and Stripper Assembly.The FPHs are designed, manufactured and inspected in accordance with API Spec 16Aand API RP 5C7.The resistance to stress corrosion by Hydrogen Sulphide ... -

API 6A Wellhead Mud Gate Valves

Mud gate valves are solid gate, rising stem, gate valves with resilient seals, these valves are designed in accordance with API 6A standard. It is mainly used for mud, cement. fracturing and water service and are easy to operate and simple to maintain.

-

API 6A low torque Plug Valves

Plug valve is a necessary part in cementing and fracturing operation in oil and mining fields as well as similar high pressure liquid control. It features compact structure, easy maintenance, low torque, quick opening and easy operation that it is the most ideal valve among cementing and fracturing manifolds right now. (Remarks: valve can also be opened or closed easily under 10000psi.)

-

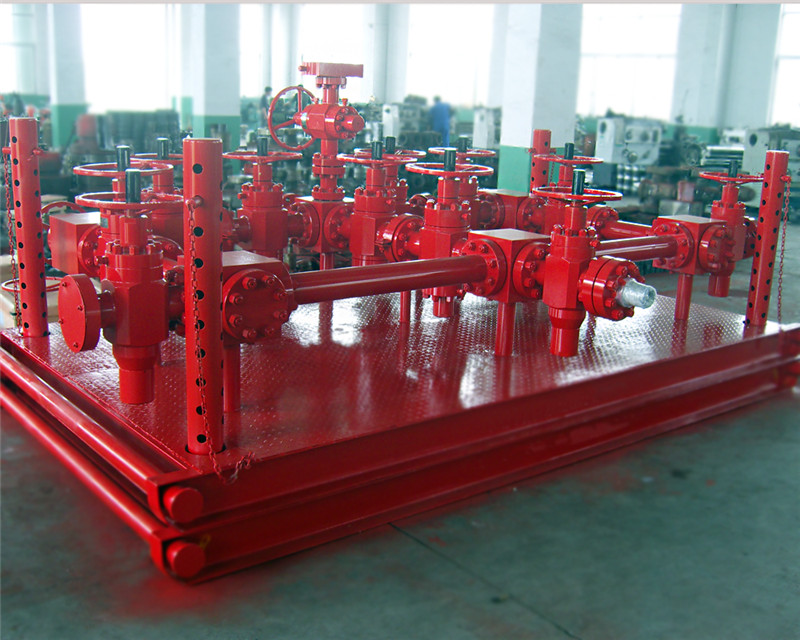

API 16C Choke & Kill manifolds

Kill manifold is a necessary equipment for controlling overflow and blowout, and implementing pressure control technology for oil and gas wells.

During the drilling process of oil and gas wells, once the drilling fluid in the wellbore is contaminated by the formation fluid, the balance between the static liquid column pressure of the drilling fluid and the formation pressure will be disrupted, leading to overflow and blowout.

When it is necessary to circulate contaminated drilling fluid or pump drilling hydraulic wells with adjusted performance in order to rebuild this balance relationship, but normal circulation cannot be achieved through the drill string, the drilling fluid with adjusted performance can be pumped into the well through the kill manifold to control the pressure of the oil and gas well. -

API 6A Wellhead manifold Check Valves

Check valve is designed and produced entirely according to the requirements of API 6A 《Equipment Specifications for Wellhead and Christmas Tree》, able to be used interchangeably with corollary equipment at home and abroad that is inline with API 6A Standard. The core adopt sulfide-resistance steel and able to be used in H2S condition, valve body made by alloy steel forging with good performance. Two types of Check valves are offered by landrill: Swing type and Lift type.

-

API 6A Wellhead Slab Gate Valve

Features

1.Full-bore design effectively eliminates pressure drop and eddy currents and slows down solid particles in the fluid

flushing of valves;

2.Unique sealing design, so that the switching torque is greatly reduced;

3.Metal seals are made between the bonnet and the valve body, the valve plate and the valve seat ring;

4.Metal sealing surface spray (overlay) welding cemented carbide, with good wear resistance, corrosion resistance;

5.The seat ring is fixed by the fixed plate to maintain good stability;

6.The stem is equipped with an inverted sealing mechanism to facilitate the replacement of the stem sealing ring with pressure. -

API 16C Choke & Kill manifolds

Choke manifold is the necessary equipment to control kick and implement pressure control technology of oil and gas wells. When the blowout preventer is closed, a certain casing pressure is controlled by opening and closing the throttle valve to maintain the bottom hole pressure slightly higher than the formation pressure, so as to prevent the formation fluid from flowing into the well further. In addition, choke manifold can be used to relieve pressure to realize soft shut in. When the pressure in the well rises to a certain limit, it is used to blowout to protect the wellhead. When the well pressure increases, the fluid in the well can be released to control the casing pressure by opening and closing the throttle valve (manual adjustable, hydraulic and fixed). When the casing pressure is very high, it can directly blow off through the gate valve.

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141