Products

API 7-1 4145Hmod and Non-mag Integral Blade Stabilizer

Product Description

API Connection

All API connections comply with dimensional requirements specified in API spec 7 and API RP 7G. Common sizes and styles are summarized in the table below. Premium connections are available on request.

Hard-facing Types

HF 1000 (crushed carbide)

HF 2000 (crushed carbide and tungsten traps)

HF 3000 (T.C.I. spray matrix spray powder and tungsten insert)

HF 4000 (buttons)

HF 5000 (technodur)

Options Available

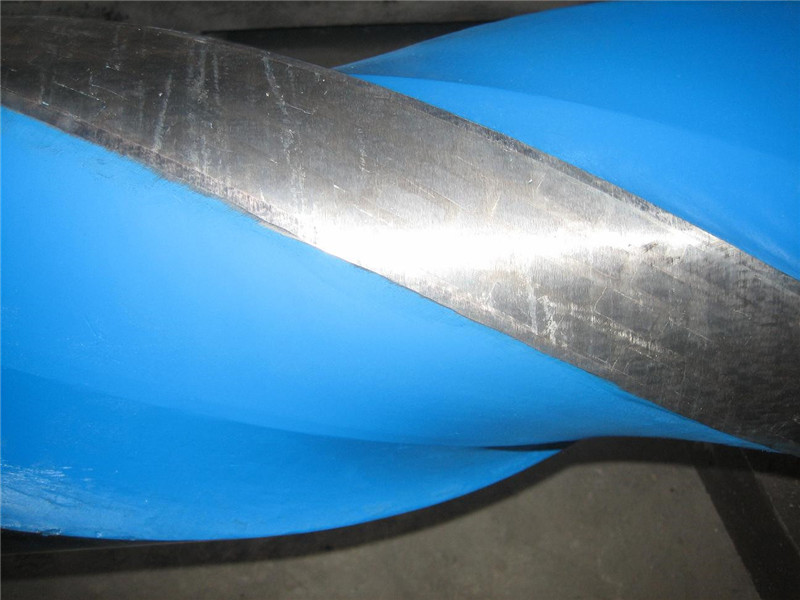

1. Integral blade, Welded blade/ Spiral Blade, Straight Blade

2. Alloy steel, Non-magnetic steel

3. String Type, Near Bit Type

Product Specification

| Bit Size | Working OD | End OD of body(mm) | ID | Length | Thread code on both ends | |||

| (in) | (mm) | (mm) | (mm) | Drill string type | Near bit type | |||

| Top | Down | Top | Down | |||||

| 6 | 152.2 | 121 | 51 | 1200 | NC38 | 3 1/2 REG | ||

| 6 1/4 | 158.7 | |||||||

| 6 1/2 | 165.1 | |||||||

| 7 1/2 | 190.5 | 159 | 57 | 1600 | NC46 | 4 1/2 REG | ||

| 7 7/8 | 200 | |||||||

| 8 3/8 | 212.7 | 159 | 71 | 1600 | NC46 | |||

| 165 | 1800 | NC50 | ||||||

| 8 1/2 | 215.2 | 159 | ||||||

| 165 | ||||||||

| 8 3/4 | 222.2 | 178 | ||||||

| 9 1/2 | 241.3 | 178 | 1600 | NC50 | NC50 | NC50 | ||

| 9 5/8 | 244.5 | 197 | 1800 | 6 5/8 REG | ||||

| 9 7/8 | 250.8 | |||||||

| 12 1/4 | 311.2 | 203 | 76 | 1800 | NC56 | NC56 | NC56 | 6 5/8 REG |

| 209 | 6 5/8 REG | 6 5/8 REG | 6 5/8 REG | |||||

| 16 | 406 | 229 | 2000 | NC61 | NC61 | NC61 | NC61 | |

| 17 1/2 | 444.5 | 241.3 | 2200 | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG | |

| 24 | 609.6 | |||||||

| 26 | 660.4 | |||||||

| 28 | 711.2 | |||||||

| Note: Stabilizer can be made according to customer’s special requirement. | ||||||||

Product Specification

Landrill is a professional drilling stabilizer manufacturer with more than 15 years experience in this industry. Our products are designed and manufactured to the highest standards of quality and durability, and we are committed to providing the best products and services to our customers.

Our durable drill stabilizers feature hard facing technology to ensure superior wear resistance and long-lasting performance. Our integral helical blade technology also enhances the performance of the stabilizer, making it a popular choice among drilling professionals worldwide.

Our API7-1 certified drilling stabilizers are available in a variety of sizes and specifications to meet the unique needs of our customers. We supply stabilizers for vertical and horizontal drilling applications and offer different blade configurations to optimize performance and efficiency.

At Landrill we understand the importance of precision and reliability in drilling operations, which is why we are committed to providing the highest quality of drilling stabilizers on the market. Contact us today to learn more about our products and services, and let us help you maximize the efficiency of your drilling operations.

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141