Products

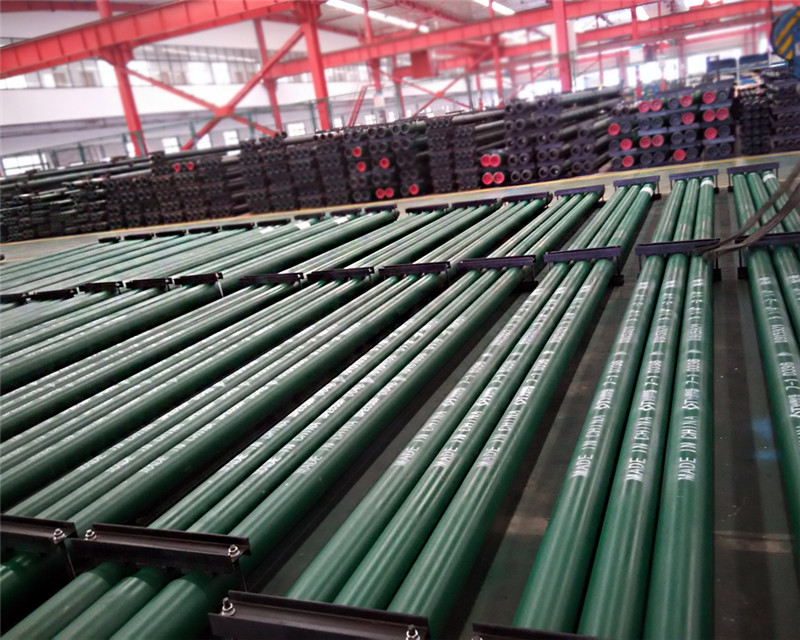

API 7-1 4145&Non-mag Drill Collar

Product Description

Ordinary drill collar is the circular cross section, the center has a water hole,the wall thickness is larger,the nozzle is smaller, the weight of per unit length is greater than the size of drill pipe almost 4- 5 times .The majority of drill collar is thread processing directly on the pipe body , but some of them also use the replaced joint.

Spiral drill collar are a kind of petroleum drilling tool .This kind of drill collar is capable of preventing differential pressure detention of tools during drilling. Spiral grooves will enable the mud to flow freely around the drill collar to use balance pressure to prevent the formation of obstruction so as to effectively prevent differential pressure jamming. The contact area against the wall of the well can be cut so as to effectively reduce the possibility of forming differential pressure obstruction. Spiral grooves will enable the mud to flow freely around the drill collar to use balance pressure to prevent the formation of obstruction so as to effectively prevent differential pressure jamming. The contact area against the wall of the well can be cut so as to effectively reduce the possibility of forming differential pressure obstruction. The weight of spiral drill collar is 4-6% less than that of the round drill collar.

Non-Magnetic Drill Collar: Non-magnetic Drill collars are made from Non-magnetic drill collar materials with low- strength by combining a proprietary chemical analysis and a rotary hammer forging process with low magnetic permeability excellent machine ability. we can supply in lengths from 10 to 42 feet and outside diameter from 31/8"to 11'.

Product Specification

| Size | O.D(mm) | I.D.(mm) | Code | Thread | Length(mm) | Weight(kg) |

| 3-1/8 | 79.4 | 31.8(1-1/4) | NC23-31 | NC23 | 9140 | 298 |

| 3-1/2 | 88.9 | 38.1(1-1/2) | NC26-35 | NC26 | 9140 | 364 |

| 4-1/8 | 104.8 | 50.8(2) | NC31-41 | NC31 | 9140/9450 | 474/490 |

| 4-3/4 | 120.6 | 50.8(2) | NC35-47 | NC35 | 9140/9450 | 674/697 |

| 5 | 127 | 57.2(2-1/4) | NC38-50 | NC38 | 9140/9450 | 725/749 |

| 6 | 152.4 | 57.2(2-1/4) | NC44-60 |

NC44 |

9140/9450 | 1125/1163 |

| 71.4(2-13/16) | NC44-60 | 9140/9450 | 1022/1056 | |||

| 6-1/4 | 158.8 | 57.2(2-1/4) | NC44-62 | NC44 | 9140/9450 | 1237/1279 |

| 71.4(2-13/16) | NC46-62 | 9140/9450 | 1134/1172 | |||

| 6-1/2 | 165.1 | 57.2(2-1/4) | NC46-65 | NC46 | 9140/9450 | 1352/1398 |

| 71.4(2-13/16) | NC46-65 | NC50 | 9140/9450 | 1249/1291 | ||

| 6-3/4 | 171.4 | 57.2(2-1/4) | NC46-67 | NC46 | 9140/9450 | 1471/1521 |

| 7 | 177.8 | 57.2(2-1/4) | NC50-70 | NC50 | 9140/9450 | 1597/1651 |

| 71.4(2-13/16) | NC50-70 | 9140/9450 | 1494/1545 | |||

| 7-1/4 | 184.2 | 71.4(2-13/16) | NC50-72 | NC50 | 9140/9450 | 1625/1680 |

| 7-3/4 | 196.8 | 71.4(2-13/16) | NC56-77 | NC56 | 9140/9450 | 1895/1960 |

| 8 | 203.2 | 71.4(2-13/16) | NC56-80 | NC56/6-5/8REG | 9140/9450 | 2040/2109 |

| 8-1/4 | 209.6 | 71.4(2-13/16) | 6-5/8REG | 6-5/8REG | 9140/9450 | 2188/2263 |

| 9 | 228.6 | 71.4(2-13/16) | NC61-90 | NC61 | 9140/9450 | 2658/2748 |

| 9-1/2 | 241.3 | 76.2(2-13/16) | 7-5/8REG | 7-5/8REG | 9140/9450 | 2954/3054 |

| 9-3/4 | 247.6 | 76.2(3) | NC70-97 | NC70 | 9140/9450 | 3127/3234 |

| 10 | 254 | 76.2(3) | NC70-100 | NC70 | 9140/9450 | 3308/3421 |

| 11 | 279.4 | 76.2(3) | 8-5/8REG | 8-5/8REG | 9140/9450 | 4072/4210 |

Features and Benefits

A hardness range of 285 to 341 BHN and a Charpy impact value of 40 ft-lbs are guaranteed for evenly distributed 16 points in any cross sections at room temperature;

Connections are phosphate coated after machining to protect the threads from corrosive elements and to prevent galling upon initial make-up;

Thread roots are cold rolled on API connections;

Pressed steel thread protectors are supplied for all drill collar that are equipped with standard connections.

Options

Stress relief groove. Stress relief features on API pin and box connections to reduce high stress concentrations thus improving the bending strength around the connection areas.

Cold rolling of thread roots has demonstrated the beneficial effects to improve fatigue resistance of the connections by minimizing crack initiation.

Hardbanding. Hardbanding at locations under and above slip recess or at pin shoulder extends the service life of the drill collars. It can also be applied in configurations specified by customers. Hardbanding at locations under and above slip recess or at pin shoulder extends the service life of the drill collars. It can also be applied in configurations specified by customers.

Slip and elevator recesses. The upper radius of elevator recess is cold rolled to improve product life. Slip and elevator recesses are machined in accordance with API Spec 7-1.

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141