1. Structural principle

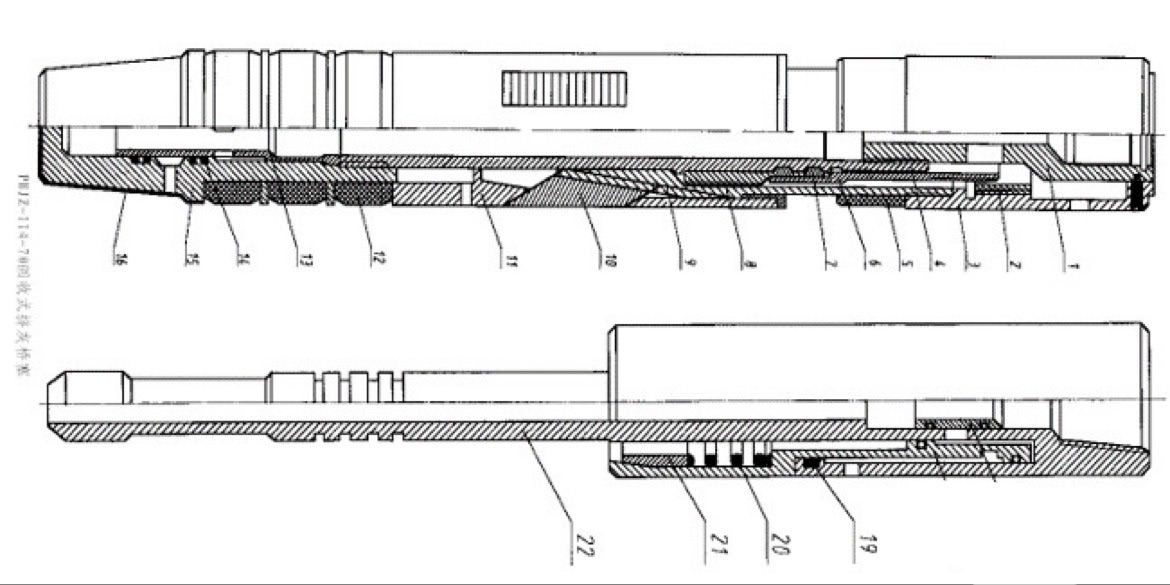

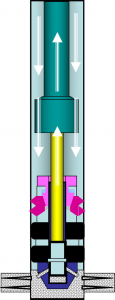

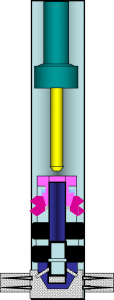

The recoverable ash-squeezing bridge plug consists of a seat seal and anchor mechanism, a locking and unsealing mechanism, a sliding sleeve switch and an anti-stick mechanism, an intubation and a salvage mechanism.

The cable setting tool or oil pipe hydraulic setting tool can be used to send the bridge plug to the predetermined position for setting and throwing away, then take out the setting and feeding tool, insert the intubation tool into the recoverable ash squeezing bridge plug, and carry out the ash squeezing operation , After squeezing the ashes, raise the intubation tube and backwash the well. After the initial setting of the mortar, the overshot can be lowered to fish out the bridge plug.

2. Work process

1. The setting and unsealing operation is the same as the conventional sealing operation.

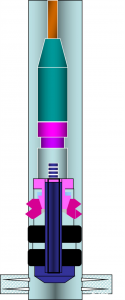

2.After the ash-squeezing bridge plug is set, connect the ash-squeezing cannula to the bottom of the tubing string and lower it into the wellbore, insert it into the mandrel of the recovery-type ash-squeezing bridge plug, and push the slide valve.

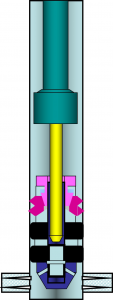

3.Replace the cement slurry with a cement truck for ash squeezing operation.

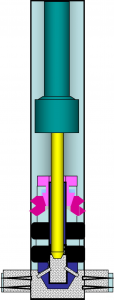

4.After the ash is squeezed, immediately lift the pipe string, pull out the intubation pipe to close the slide valve, and immediately backwash the well to wash the excess cement mortar out of the wellbore. Because the slide valve is closed, the cement slurry outside the formation or the pipe cannot flow back into the wellbore, which ensures the cementation quality and plugging effect of the cement slurry, shortens the residence time of the cement slurry in the wellbore, and reduces the cement slurry solidification pipe string.

5.If the upper layer is exploited, the Retrievable Bridge Plug of Cement Squeeze is used as a common bridge plug seal and can be put into production directly; if the lower layer is mined, the unsealed salvage string is put into the well to remove the bridge plug. After the bridge plug is pulled out, put grinding shoes down the well to drill out the cement plug. Since there are no metal parts, drilling and grinding is easy.

3. Technical features

1. Flexible setting method: The bridge plug can be sent into the setting by cable-type setting tool or hydraulic setting tool, and the appropriate setting tool can be selected according to the specific well conditions.

2. Accurate setting control: The setting force of the bridge plug is controlled by the tension rod (ring), which ensures the safe and reliable setting of the bridge plug. At the same time, it ensures that the setting tool can be safely lifted out of the wellbore under complex conditions.

3. Reliable anti-jamming design: The slip part adopts a built-in slip structure, and the bridge plug is not easy to encounter resistance and jamming when it is lifted and lowered in the shaft. After setting, the bridge plug slips and rubber tube are automatically centered, and can be safely used in wells with any inclination and horizontal wells.

4. Unique anchoring mechanism: The bridge plug uses the ingenious combination of slips, slip cones, and slip outer cylinders. It has good bidirectional pressure bearing capacity and can be applied to casings of various levels.

5. Safe unsealing mechanism: The unsealing of the bridge plug is carried out step by step in the order of the locking mechanism, the sealing mechanism, and the slip mechanism. No matter whether the upper and lower pressures of the bridge plug are balanced, the required unsealing force is very small.

6. It is easy to drill and grind the ash plug: after the ash squeezing operation of the recyclable ash-squeezing bridge plug, the bridge plug can be pulled out, and it is easy to drill and grind the ash plug.

7. Possess certain drillability: the bridge plug has a compact structure, the upper structure is made of materials with better drillability, and the internal locking mechanism is on the top of the bridge plug, even if the bridge plug cannot be fished out due to abnormal reasons, it can still be easier to drill out.

Post time: Jul-28-2023

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141