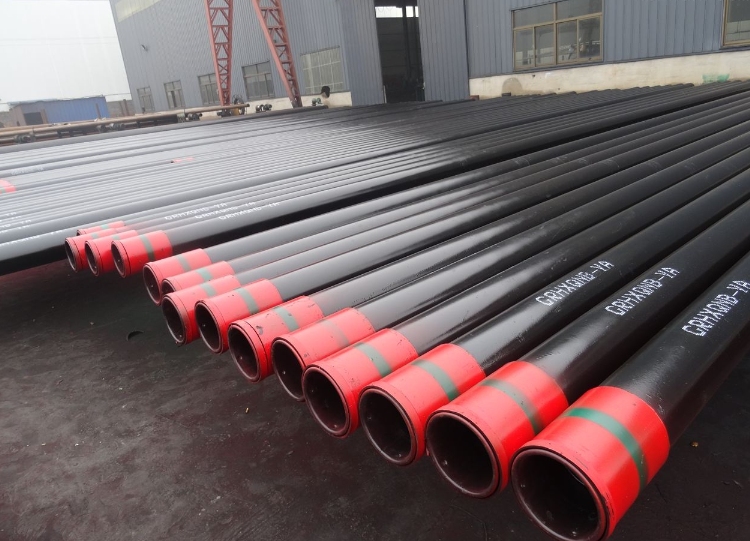

In the oil and gas industry, four types of casing are commonly used:

1.Conduit: Conduit is the first conduit installed to support the weight of the drilling rig and prevent the borehole from collapsing during drilling. Conductor Casing: Typically, conductor casing is the largest diameter casing used in drilling operations. It ranges in size from 20 to 42 inches in diameter. Conductor casing is usually made of low-grade carbon steel, such as J55 or N80, to provide stability during the initial drilling phase.

2. Surface casing: is the second casing installed to provide protection for freshwater areas and prevent contamination. Its diameter is usually larger than that of the conductor housing. Surface Casing: Surface casing is the first casing set in the well after drilling the conductor hole. It provides protection for shallow groundwater and isolates the upper formations. The commonly used sizes for surface casing are 13⅜ to 20 inches in diameter. Material grades for surface casing can include carbon steel grades like J55, K55, N80, or higher-strength materials like L80 or C95

3. Intermediate Casing: This casing is installed at different depths depending on well conditions and is used to protect the wellbore from formation fluids and pressures. It provides additional support and isolation to the well. Intermediate Casing: Intermediate casing is set at intermediate depths and provides additional support to the wellbore. Intermediate casing sizes range from 7 to 13⅜ inches in diameter, depending on the well design. Material grades for intermediate casing can include L80, C95, or higher-strength grades like T95 or P110.

4. Production Casing: This is the final casing installed in the well after drilling is complete. It provides structural integrity to the well and isolates the production zone from surrounding formations to prevent leaks and maintain well productivity. These four types of casing are commonly used in the oil and gas industry, but variations may exist depending on specific well conditions and regulatory requirements. Intermediate Casing: Intermediate casing is set at intermediate depths and provides additional support to the wellbore. Intermediate casing sizes range from 7 to 13⅜ inches in diameter, depending on the well design. Material grades for intermediate casing can include L80, C95, or higher-strength grades like T95 or P110.

It’s important to note that casing sizes and material grades can vary based on specific well requirements and regional standards. Various alloys, corrosion-resistant materials, and accessories can also be utilized depending on well conditions, such as sour gas environments or high-pressure/high-temperature wells.

Post time: Jul-26-2023

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141