1. Purpose of kelly valve

The kelly valve is a manual control valve in the drill string circulation system and is one of the effective tools to prevent blowout. Kelly valves can be divided into upper kelly valves and lower kelly valves. The upper kelly valve is used between the lower end of the faucet and the kelly; the lower kelly valve is used between the lower end of the kelly and the kelly protection joint. Drilling fluid can flow freely through the kelly valve without pressure drop. Use a special wrench to turn it 90° according to the instructions to switch it on and off.

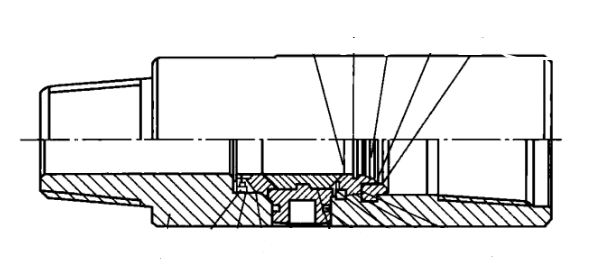

2. Kelly valve structure and working principle

The upper and lower kelly valve are composed of a body, a lower ball seat, a spring, an operating key, a ball valve, an open retaining ring, an upper ball seat, a retaining ring sleeve, an elastic retaining ring and a seal, an accessory wrench, etc. The sealing principle is that the spring supports the ball seat to position the ball and make it have a certain preload. The ball and the seal of the ball seat are in close contact. When the ball is released, the water eyes are unobstructed. When closed, the spherical surface seals all the water eyes. The pressure of the inner annulus acts on the ball, making the ball and ball seat in a high-pressure sealing state.

3. How to use the kelly valve

(1) Before use, use a special wrench to rotate the operating key to see if it can rotate flexibly, in place or out of position;

(2) After connecting the upper and lower ends of the kelly, use the wrench again to test the flexibility of the operating keys before going down the well;

(3) When a kick or blowout occurs on the kelly in the well, the upper or lower plug valve of the kelly should be closed at the nearest location;

(4) During normal operation, close the lower plug valve before unloading the kelly to prevent drilling fluid from splashing on the drill floor;

(5) Insist on opening and closing the upper and lower cocks of the kelly regularly. For example, when connecting a single piece or using the movable upper and lower cocks of the kelly at regular intervals, to avoid being rusted and unable to open and close normally;

(6) After connecting a single piece, the closed plug valve should be opened in time to avoid holding the pump when starting the pump;

(7) The plug valve wrench should be placed far away from the wellhead to prevent it from falling into the well or being lost;

(8) When selecting a plug valve, ensure that its maximum working pressure is consistent with the pressure level of the wellhead blowout preventer group.

Post time: Feb-23-2024

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141