The drilling tool bypass valve is a backup safety valve of the circulation system. When the overflow drill bit nozzle is blocked due to various reasons and the well cannot be killed, opening the drilling tool bypass valve can restore normal drilling fluid circulation and carry out In operations such as well killing, under normal circumstances, before drilling the oil and gas layer, the drilling tool bypass valve is connected to the predetermined position of the drill string.

1) Structure of drilling tool bypass valve

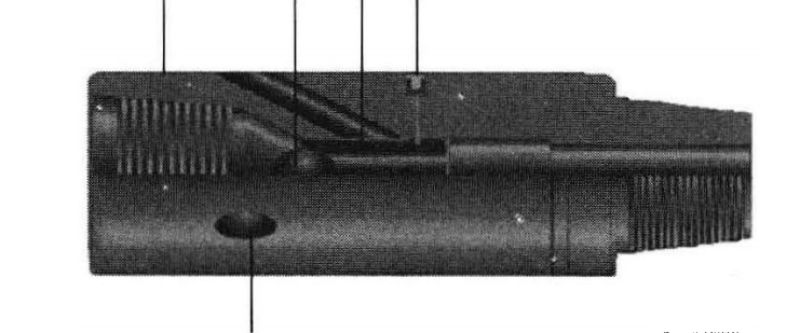

The picture above is a schematic structural diagram of the drilling tool bypass valve. It is mainly composed of valve body, valve seat sliding sleeve assembly, bypass hole, steel ball, pin, “O” type sealing ring, etc.

2) Working principle of drilling tool bypass valve

Once it is found that the drill bit water hole is blocked and cannot be unblocked, remove the kelly and throw the ball, then connect the kelly so that the ball falls to the drill tool bypass valve seat. After pumping with a small displacement, as long as the pump pressure rises to When the pressure reaches a certain value, the fixed pin will be cut off, causing the valve seat to move downward until the bypass hole is fully opened. The pump pressure will then drop, thereby establishing a new circulation channel, and construction work can begin.

3) Use of drilling tool bypass valve

(1) To keep the drilling fluid in manholes clean, the bypass valve should be opened in advance to prevent the drill bit water hole from being clogged.

(2) The steel ball of the bypass valve should be prepared and placed before use so that it can be accessed in time when needed.

(3) In order to ensure that the sliding sleeve of the bypass hole of the required bypass valve can be opened smoothly, it is generally recommended that the bypass valve be installed between the drill collar and the drill pipe or 30 to 70m away from the check valve. Bypass valves for horizontal wells and highly deviated wells are installed in the drilling tools in the 50° to 70° well section.

(4) The drilling tool bypass valve is required to be managed according to the use of special tools for entering the well. It is required to create a record card to record in detail the time of use of the manhole and other relevant parameters. Before each drilling operation, technicians and drillers will check whether there are blockages, leaks and leaks. Seal failure, etc.

Post time: Mar-04-2024

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141