1.What is downhole operation?

Downhole operation is a technical means to ensure the normal production of oil and water wells in the process of oilfield exploration and development. Oil and natural gas buried thousands or thousands of meters underground are valuable underground resources. These oil treasures are mined through rock passages drilled through underground oil layers to the ground at considerable cost. In the long-term production process, the oil and water wells are continuously affected by the oil and gas flow, so that the oil wells are changing all the time, gradually aging, and various types of failures occur, resulting in the failure of normal production of the oil and water wells. Even discontinued. Therefore, it is necessary to carry out downhole operations on the oil and water wells that have problems and failures, so as to restore the normal production of the oil and water wells. Downhole operations mainly include maintenance of oil and water wells, overhaul of oil and water wells, reservoir reconstruction and oil testing.

2. Maintenance work

In the process of oil production and water injection in oil and water wells, due to formation sand and salt production, formation burial, pump sand sticking, salt sticking, or pipe string wax deposition, pump valve corrosion, packer failure, tubing, oil pumping Due to various reasons such as rod breakage, the oil and water wells cannot be produced normally. The purpose of oil and water well maintenance is to restore normal production of oil and water wells through operation and construction.

Oil and water well maintenance includes: water well test injection, seal replacement, water absorption profile measurement; oil well pump inspection, sand cleaning, sand control, casing wax scraping, water plugging and simple downhole accident treatment and other workover operations.

Oil well inspection pump

When the oil well pump is working in the well, it is attacked by sand, wax, gas, water and some corrosive media, which will damage the pump components, cause the pump to fail, and the oil well will stop production. Therefore, checking the pump is an important means to maintain the good performance of the pump and maintain the normal production of the pumping well.

The main work content of the oil well inspection pump is to lift and lower the sucker rod and oil pipe. The reservoir pressure is not high, and the snubbing device can be used for downhole operations. For wells with falling objects or slightly higher formation pressure, brine or clean water can be used for downhole operations after the well is suppressed, and mud killing should be avoided.

Special attention should be paid to the pump inspection work: accurate calculation of the pump depth, reasonable combination of sucker rods and tubing, and running qualified sucker rods, tubing and deep well pumps, etc., which are important measures to improve pump efficiency.

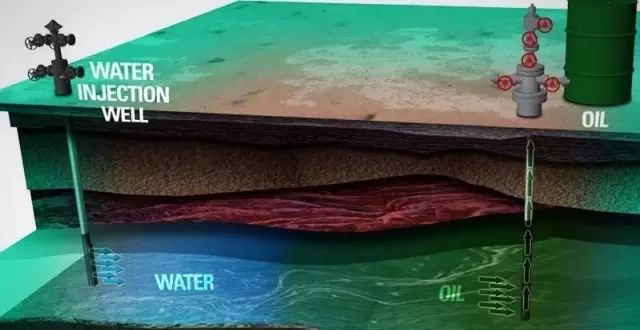

Oilfield water injection

Oilfield water injection is an effective means to maintain oil layer pressure, and an effective measure to maintain long-term stable and high production in oilfields, increase oil recovery speed and ultimate recovery rate.

After the water injection development plan of the oil field is determined, in order to obtain relevant information such as injection pressure and injection volume of each injection layer, a trial injection stage must be passed before the formal water injection.

Trial injection: before the oil well is formally put into water injection, the test and construction process of new well injection or oil well transfer injection is called trial injection. Specifically for a water injection well, it is to remove the mud cake, debris, and dirt on the well wall and bottom of the new well or the oil well before the injection, and determine the water absorption index of the water injection well, laying a good foundation for the implementation of the water injection plan. Trial injection is divided into three stages, namely liquid drainage, well flushing, transfer injection and necessary additional injection measures.

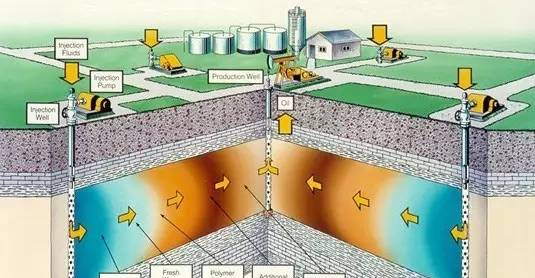

Selective water blocking

In the process of oilfield development, the water out of the oil layer will seriously affect the oilfield development work, and even reduce the ultimate recovery rate of the oilfield. After the oil well produces water, firstly determine the water level, and then use the water shutoff method to seal it. The purpose of water plugging is to control the flow of water in the water-producing layer and change the flow direction of water in the water flooding oil, improve the efficiency of water flooding, and try to make the water production of the oilfield decrease or stabilize for a period of time, so as to maintain the increase in oil production or Stable production and enhanced oilfield ultimate recovery.

Water shutoff technology can be divided into two categories: mechanical water shutoff and chemical water shutoff. Chemical water shutoff includes selective water shutoff and non-selective water shutoff and adjustment of water absorption profile of water injection wells.

1. Mechanical water plugging is to use packers and downhole supporting tools to seal the water outlet layer in the oil well. This kind of water shutoff has no selectivity. During the construction, the pipe string must be equipped to make the packer seat seal accurate and tight, so as to achieve the purpose of water shutoff. This water blocking method can seal the upper layer to mine the lower layer, seal the lower layer to mine the upper layer, or seal the middle layer to mine both ends and seal the two ends to mine the middle layer.

2. Chemical water plugging is to inject chemical plugging agent into the water outlet layer, and use the chemical properties of the plugging agent or the substances generated by the change of chemical reactants in the formation to seal the water outlet channels of the formation and reduce the comprehensive water cut of the oil well.

Selective water plugging is to extrude some high molecular polymers or some inorganic substances that precipitate and solidify when encountering water into the formation. The hydrophilic gene in the polymer has affinity and adsorption to water when it meets water, and expands; it shrinks when it meets oil, and has no adsorption effect. Inorganic substances that form precipitation and solidification when meeting with water can block the water outlet channel of the formation, and will not produce precipitation or solidification when meeting with oil.

Non-selective water shutoff mostly relies on sedimentation particles to block formation pores. This water plugging method not only blocks the water channel, but also blocks the oil channel.

Oil well overhaul

In the production process of oil wells, often due to downhole accidents and other reasons, the oil and water wells cannot be produced normally, especially after the occurrence of downhole sticking and falling objects, the production of oil and water wells will be reduced or stopped, and in severe cases, the oil and water wells will be scrapped. Therefore, it is an important measure to ensure the normal production of the oil field to prevent the occurrence of downhole accidents and deal with them quickly. The main contents of the overhaul of oil and water wells include: downhole accident handling, complex falling object salvage, casing repair, sidetracking, etc.

The overhaul of oil and water wells is complex, difficult, and highly technically demanding. Furthermore, there are many reasons for downhole accidents, and there are many types of downhole accidents. Common downhole accidents are generally divided into three categories: technical accidents, downhole stuck pipe accidents and downhole falling object accidents. When dealing with it, it is necessary to find out the nature of the accident, find out the cause of the accident, and take corresponding technical measures to properly handle it. All process technical accidents occur during the process, and can be dealt with in advance according to the cause of the accident during the construction process. Downhole sticking accidents and downhole falling object accidents are the main downhole accidents that affect the normal production of oil and water wells. ACCIDENT. It is also a large number of common underground accidents.

Post time: Aug-11-2023

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141