Oil drilling hose is a special pipeline device used in oil field drilling operations. It undertakes the important task of transporting media such as drilling fluid, gas and solid particles, and is an indispensable part of the oil drilling process. Oil drilling hoses have the characteristics of high pressure resistance, corrosion resistance, wear resistance, etc., and can operate stably under harsh working conditions to ensure the smooth progress of drilling operations.

API Spec 7K Hose

Application: apply to drilling, cementing, well repair and other operations, as a flexible connection part for mud manifolds, cementing manifolds, etc., to transport water-based mud, oil-based mud, etc. under high pressure

Inner Tube: UPE /NBR / SBR / HNBR/PTFE

Tube Type: full flow

Reinforcement: 2-6 layers of high tensile spiral steel wire

Outer Layer: abrasion resistant synthetic rubber

Temperature Range: -25℃~+80℃/-30℃~+160℃

Connectors: integral union or as per customers’

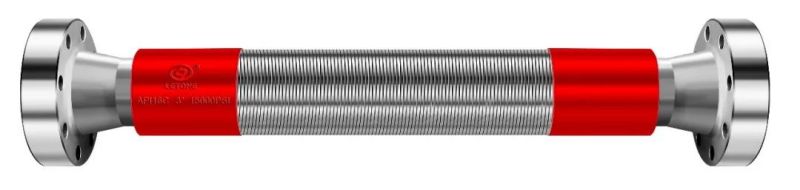

API Spec 16C Hose

Application: flexible connection in the chock and kill manifolds for delivery oil-gas mixture that containing hydrogen sulfide (H2S) and other dangerous gases and various water-based, oil-based and foam killing fluids under high pressure.

Inner Tube: HNBR

Bore Type: full flow

Reinforcement: 4-6 layers of high tensile super flexible spiral steel wire or steel cable

Outer Layer: high temperature and fire resistant synthetic rubber (resistant to 704 ℃ open fire for 30 minutes)

Protective Layer: stainless steel armor

Temperature Range:

-55℃~+150℃(-67℉~+302℉)

Connectors: integral union or integral flange

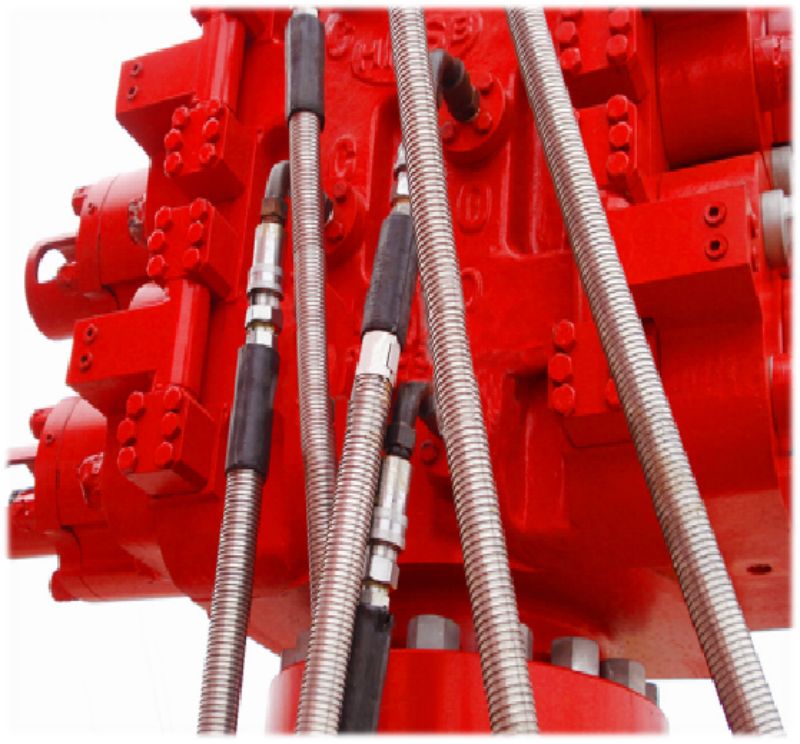

API Spec16D Hose

API 16D is the hydraulic line that powers the blowout preventer. But API 16D is not an ordinary hydraulic hose. In addition to the basic requirements of high pressure resistance, API 16D hose is also required to pass a 30-minute fire resistance test (704°C) to ensure that the hose can maintain power transmission in the extreme case of a blowout and fire. Close the wellhead promptly.

Application: hydraulic control line for remotely control the blowout preventer (BOP) at high pressure.

Hose Construction

Inner Tube: NBR

Bore Type: full flow

Reinforcement: 4 layers of high tensile super flexible spiral steel wire

Outer Layer: high temperature and fire resistant synthetic rubber

Protective Layer: stainless steel armor

Temperature Range: -45℃~+100℃(-49℉~+212℉)

Fire resistance meets API Spec. 16D, 704℃×5min

Post time: Dec-27-2023

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141