- 1.Junk Milling Shoes:used for grinding downhole falling objects,especially small pieces of falling objects and repairing fish tops.It is composed of the shoe body and YD alloy or wear-resistant materials,relying on the bottom of the alloy and wear-resistant materials under the action of bit weight to grind down the debris,and the debris,and the debris is brought out of the thrground with the circulating liquid.

2.Concave Milling Shoes : used for grinding small pieces of downhole and other unstable falling objects.The concave milling shoe is used to grind down the downhole material by surfacing YD alloy or other wear-resistant material.

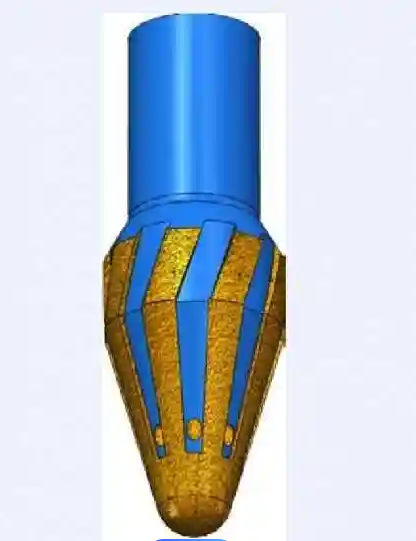

2.Concave Milling Shoes : used for grinding small pieces of downhole and other unstable falling objects.The concave milling shoe is used to grind down the downhole material by surfacing YD alloy or other wear-resistant material. - 3.Collar Milling Shoes :specialiy designed for milling with internal holes and in the downhole in the uncertain and shaking of falling objects,such as drill pipe, drill collar, oil pipe, etc.

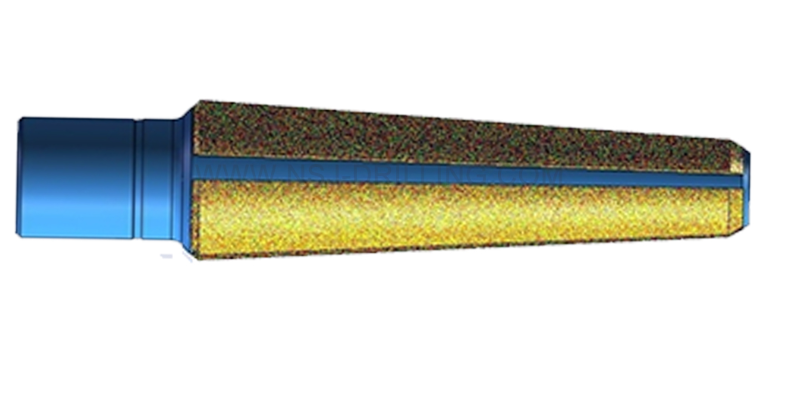

4.Taper Miloing Shoes : used for repairing small local deformation of casing and cleaning up debris on well wall. Taper milling shoes are suitable for dressing small local deformation of casing and cleaning debris on the well wall.

4.Taper Miloing Shoes : used for repairing small local deformation of casing and cleaning up debris on well wall. Taper milling shoes are suitable for dressing small local deformation of casing and cleaning debris on the well wall.

5.Ball Junk Milling Shoes :used for grinding the iron and steel stuck in the well can not be salvaged. It is ground by YD alloy surfacing on the underside, and there is a ball on the grinding cylinder to straighten it and prevent damage to the inner wall of the casing during milling.

6.Pear shaped Milling Shoes: used for gringing small local deformation of casing, repairing the rolling caused by drilling and the burr and flash caused byperforating,cleaning up the mineral and other hard debris remaining on the well wall.

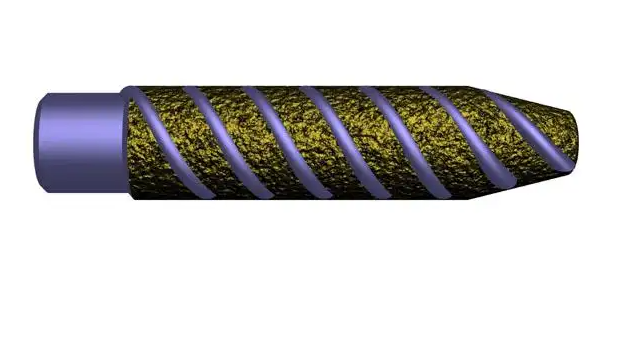

7. Cylindrical milling Shoes:used to repair slightly bent or slightly defoumed casing,repair the lower liner encountered resistance in the well saction and repair the fracture dislocation.

Junnie LiuMobile/Whatsapp:+0086-158 7765 8727

Junnie LiuMobile/Whatsapp:+0086-158 7765 8727

Email: landrill@landrilltools.com

Web: www.landrilltools.com

Post time: Dec-30-2024

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141