A Drilling Roller Reamer is a downhole tool used in the oil and gas industry to enlarge and stabilize wellbores during drilling operations. It helps maintain hole size, improve wellbore quality, and ensure smoother drilling by removing irregularities.

Key Features:

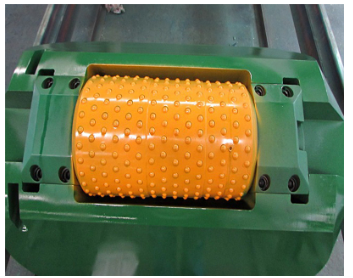

1.Roller Cutters – Equipped with hardened, rotating cutters that ream the borehole while drilling.

2.Stabilization – Helps maintain wellbore trajectory and reduces vibration.

3.Integrated or Standalone – Can be part of a Bottom Hole Assembly (BHA) or used as a separate reaming tool.

4.Durability – Made of high-strength materials to withstand abrasive formations.

5.Hydraulic Efficiency – Designed to allow proper mud flow for cooling and cuttings removal.

Applications:

1.Hole Enlargement – Expands the wellbore to the desired diameter.

2.Wellbore Smoothing – Removes ledges, doglegs, and irregularities.

3.Directional Drilling – Helps maintain well path in deviated or horizontal wells.

4.Casing & Liner Runs – Ensures sufficient clearance for casing/liner installation.

Types of Roller Reamers:

1.Fixed-Blade Reamers – Non-retractable cutters for consistent reaming.

2.Expandable Reamers – Cutters can extend/retract as needed.

3.Near-Bit Reamers – Positioned close to the drill bit for immediate hole conditioning.

Advantages:

1.Reduces torque and drag.

2.Enhances drilling efficiency.

3.Improves wellbore quality for better cementing and completion.

If you are interested in Drilling Roller Reamer, contact us today to get the best quotation!

Junnie Liu

Mobile/Whatsapp:+0086-158 7765 8727

Email: landrill@landrilltools.com

Post time: Apr-17-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141