The drill bit is a key component of drilling equipment. Its main function is to break rocks and form boreholes, and it is also one of the primary drilling tools. The specifications and shapes of drill bits should vary according to different working environments and geographical conditions. During oil drilling operations, drill bits should be selected reasonably and scientifically based on specific requirements and detailed design plans. In specific drilling work, scientific selection of drill bits and reasonable determination of drilling fluid are essential to improve the work efficiency and quality of oil drilling.

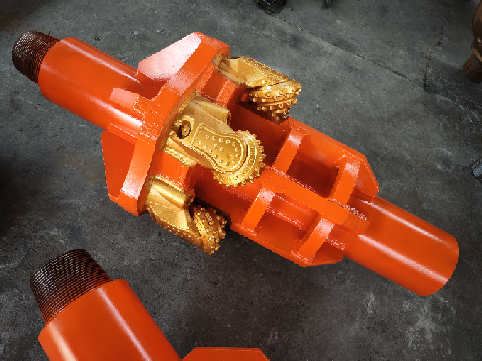

1.Tricone Drill Bits: Reliable, Versatile, Suitable for Soft to Medium Formations

1.Tricone Drill Bits: Reliable, Versatile, Suitable for Soft to Medium Formations

A tricone drill bit consists of three toothed cones. During drilling, the cones roll to crush rock, making it suitable for soft to medium-hard rock formations.

Subtypes & Performance:

Steel-Tooth Tricone Drill Bits: Low cost but fast wear.

Insert Tricone Drill Bits: Longer service life in harder formations.

Both types can effectively handle variable formations.

Key Advantages:

Ideal for exploration wells where the upcoming rock type is uncertain, as they excel in mixed formations that are challenging for other drill bits.

2.PDC Drill Bits: High-Speed Cutting for Hard, Abrasive Rock

PDC (Polycrystalline Diamond Compact) drill bits use diamond cutters—an extremely hard material that enables fast rock penetration. Unlike tricone drill bits (which crush rock), PDC drill bits shear rock.

Key Advantages:

Faster drilling speed in hard rock and longer cutter edge retention. Although the upfront cost is higher, overall costs are usually lower due to improved drilling efficiency.

Application Status:

Most companies now use PDC drill bits for hard formations. In recent years, PDC drill bit performance has improved significantly; new designs cover more specifications than older models.

3.Natural Diamond Drill Bits: Precision Drilling for Ultra-Hard Formations

Natural diamond drill bits feature real diamonds embedded in metal, designed to drill through the hardest rocks that other bits cannot penetrate. They drill slowly but steadily through such impenetrable formations.

Applicable Scenarios:

Only used for ultra-hard rocks like quartzite. Despite their high cost, they are sometimes the only option—geothermal wells often require this type of drill bit.

4.Steel-Tooth Drill Bits: Cost-Effective Optionfor Soft Formations

Steel-tooth drill bits have basic steel teeth on a tricone body, making them the most economical choice for soft rock drilling. They perform well in clay, sandstone, and soft shale.

Key Features:

Can be re-sharpened in the field; simple design with low risk of breakage. However, they dull quickly in formations harder than soft rock.

Applicable Scenarios:

Still practical for shallow wells in soft formations, or projects with tight budgets and simple formation conditions.

5.Drag Bits: Lightweight Design for Shallow & Soft Formation Applications

Drag bits have fixed blades that scrape the formation. They have no moving parts (reducing the risk of damage) and a lightweight design, which is advantageous in specific applications.

Applicable Scenarios:

Best suited for soft, homogeneous rock. Unlike other bits, they do not ball up (accumulate sticky material) in viscous clay. Some new models are equipped with PDC cutters on their blades.

Limitations:

Only applicable to soft rock formations; cannot handle hard streaks or mixed formations. Blade wear may cause drilling issues if not monitored.

6.Core Bits: Essential Tools for Formation Sampling & Data Retrieval

Core bits cut rock samples and bring them to the surface, providing physical formation samples for testing. Specialized equipment is required to handle the retrieved cores.

Design & Cutter Selection:

Different designs are used for different rock types—some use PDC cutters, while others use diamond cutters. Clean cutting is essential to preserve the integrity of the samples.

Performance & Value:

Drilling speed is slower than conventional bits, but they provide valuable formation data. The extra time investment is worthwhile for critical wells. Related equipment includes specialized bits, directional tools, reamers, and hole openers.

If you need various types of drill bits, please feel free to contact us at any time.

Contact :May Ye

Mobile/Whatsapp:+0086-158 7765 8727

Email: landrill@landrilltools.com

Web: www.landrilltools.com

Post time: Sep-12-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141