- Drill Pipe Thread Types

Drill pipe threads connect drill string components and transmit torque, with Internal Flush (IF) and Regular (REG) as the most common types (IF, FH, REG1, Full-Hole FH, XH are rare in tool workshops).

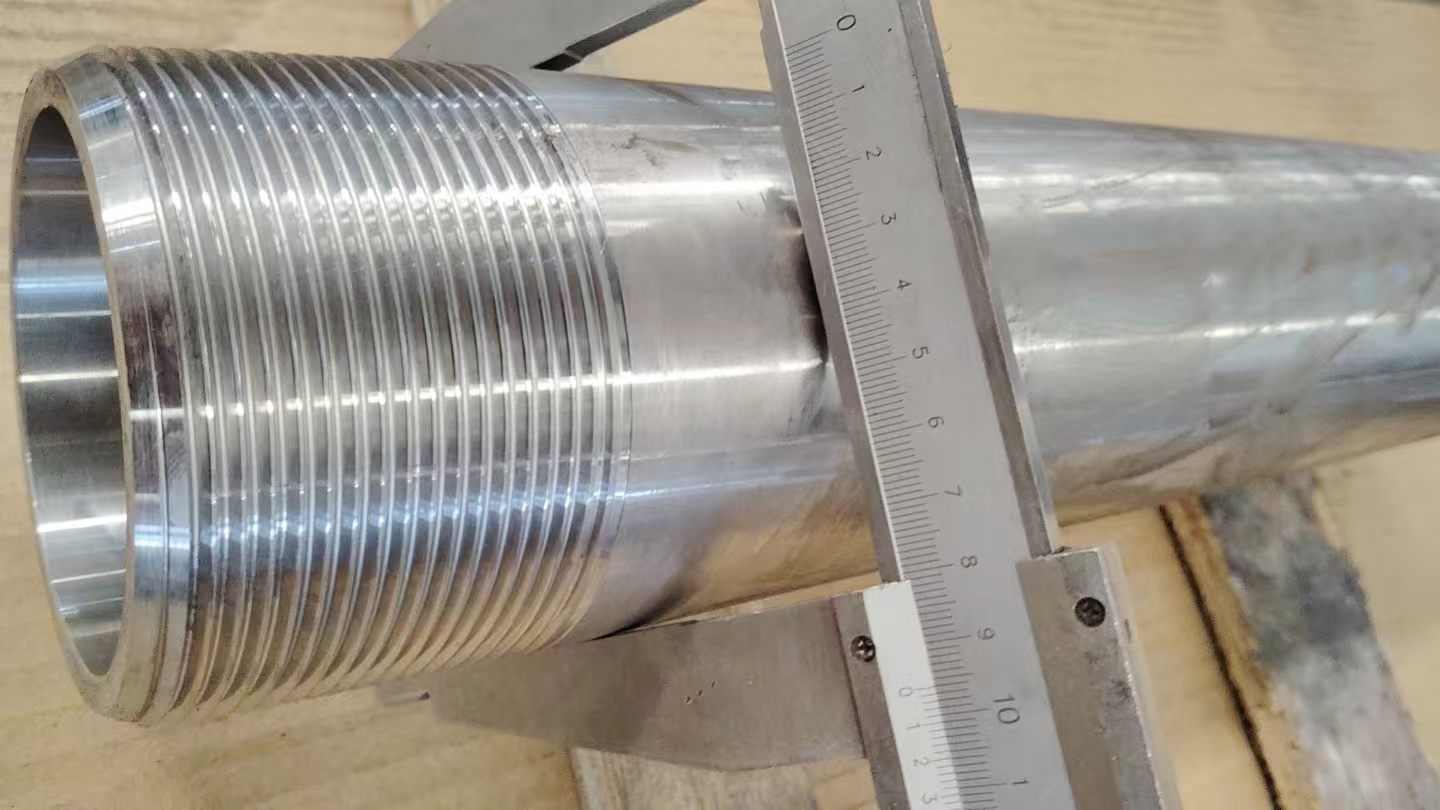

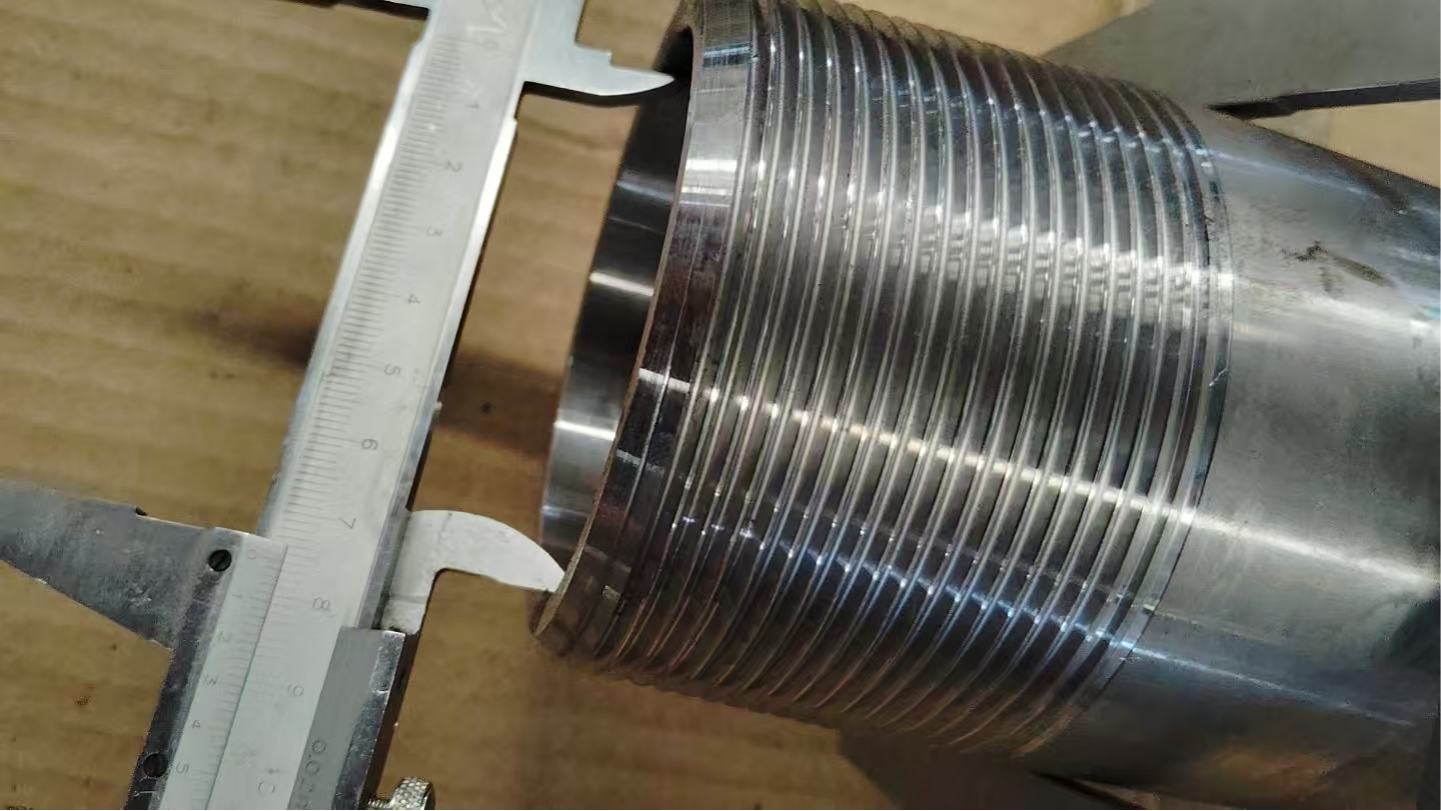

Core Differences: IF has 4 threads per inch (TPI, thick threads, small taper, size range 2-3/8″–4-1/2″); REG has 5 TPI (thin threads, large taper, used for sizes >4-1/2″, no REG for >7-5/8″).

Other Types: BTC, MT, AMT, HT55 (for specific well conditions).

- Tubing Thread Types

Main types are EU (External Upset) and NU (Non-Upset); NEW VAM and FOX are rare.

Core Differences: EU (8 TPI, external upset, sizes 2-3/8″–4-1/2″); NU (10 TPI, non-upset, sizes 1.9″–4-1/2″).

Large Sizes: >4-1/2″ uses LTC (long effective thread) and STC (short effective thread, both round threads).Marking: P=pin thread, B=box thread; NEW VAM (good airtightness for gas wells, sizes 2-7/8″–3-1/2″), FOX (size 2-7/8″). - Drill Pipe Stab Thread Types

Common types: HYDRILL CS (1.9″, external upset), HYDRILL 511 (2-7/8″, tapered threads), TSWP (4″, double-shoulder sealing, used for mill shoes), FL-4S/FL-CS (shared for 2-7/8″, 4″). - Screen Pipe & Blind Pipe Thread Types

Three main types:

BTC: Buttress thread (sizes 5-1/2″–7″, high pressure resistance).

STC: Short round thread (sizes 4-1/2″–7-5/8″, low cost).

LTC: Long round thread (sizes 4″–7″, good sealing).

- Special Thread Types

ACME: Trapezoidal thread for sealing units (sizes 3.25″–6″).

LP: Triangular cross-section for high-pressure manifolds (sizes 2″–3″).

Hammer Union: 1502, 1602 (quick connection for high-pressure hoses).

FJWP: For casing mills (withstands high torque). - Significance of Selection

Proper thread types ensure reliable connection/sealing, avoid downhole accidents (leakage, sticking), and reduce tool wear to improve drillingefficiency.Contact :Bree Zhang

Mobile/Whatsapp:+0086-183 9206 9193

Email: landrill@landrilloiltools.com

Web: www.landrilltools.com

Post time: Sep-05-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141