1. Application

The concave mill shoe is a well repair tool used for grinding small downhole fish and other unstable fish inside the casing.

2. Structure

It consists of a mill shoe body with a concave angle of 5°~30° on the bottom surface, and YD alloy or other wear-resistant materials deposited (overlay welded) on the bottom surface.

3. Working Principle

Under the action of drilling pressure, the YD alloy and wear-resistant materials on its bottom surface bite into and grind downhole fish, and the grinding debris is carried out of the ground along with the circulating well-flushing fluid.

4. Technical Specifications

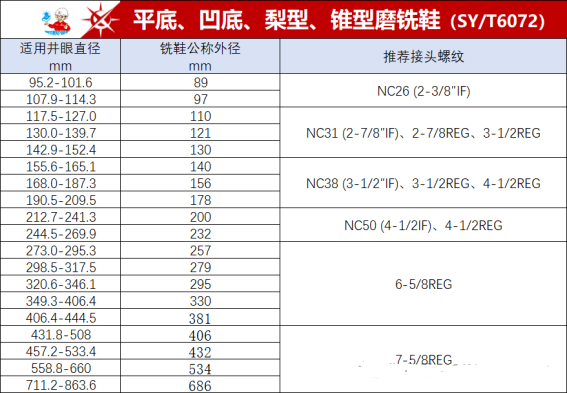

- Executive Standard: SY/T6072

- Specification and Model: (to be filled)

5. Operating Method

(1) Check that the threads are intact, the water courses are unobstructed, and the YD alloy blocks do not protrude beyond the body. Measure the tool and draw a sketch (take photos).(2) Connect and run the tool in the hole to 2–3 m above the fish. Open the pump for circulation. Once stable, rotate and lower slowly to contact the fish for grinding.

6. Precautions

(1) If there is no progress for a long time at a single point, analyze the cause and take measures to prevent casing damage.(2) Run a wiper trip if necessary.(3) Do not use on movable fish, to prevent the mill shoe from pushing the fish downward into the well or damaging the underlying fish.(4) Bypass water courses are prone to blockage by mud and sand, which affects downhole operations. In addition to pre-run inspection, adopt segmented well flushing during tripping, typically flushing once every 400 m.(5) During grinding, add a section of drill collar above the mill shoe or install a stabilizer on the drill string to ensure stable operation of the mill shoe and avoid casing damage.

7. Maintenance

(1) Clean thoroughly after use, removing all debris from the water courses.(2) Overlay weld the worn YD alloy or wear-resistant materials on the bottom surface.

Contact :Jessie Zhou

Mobile/Whatsapp:+0086-18109206861

Email: energy@landrilltools.com

Post time: Feb-09-2026

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141