Details about RTTS Packers

RTTS (Retrievable Test-Treat-Squeeze) packers are large, retrievable packers capable of withstanding bi-directional pressure. They are designed for performing multiple functions in operations such as formation testing, acidizing, and cementing, allowing for a variety of tasks to be completed in a single run. Due to their versatility, RTTS packers are frequently used in our production testing process. To better understand the internal structure of this tool, we need to examine it in detail, which will help us address issues that may arise during construction and post-maintenance handling.

1. Definition of RTTS Packers

RTTS packers are mechanically sealed, sleeve-type packers equipped with a hydraulic anchoring device. They are mainly used for fracturing and acidizing operations, but can also be used for downhole operations such as well testing, water injection, and cement squeezing.

RTTS packers are specialized tools used to seal off oil, gas, and water layers within a cased wellbore. They utilize external force to shorten the length of the rubber cylinder and increase its diameter. By sealing off the oil layer and annular space, the packer isolates the oil layer (or gas/water layers) above and below, achieving the purpose of testing oil and gas wells.

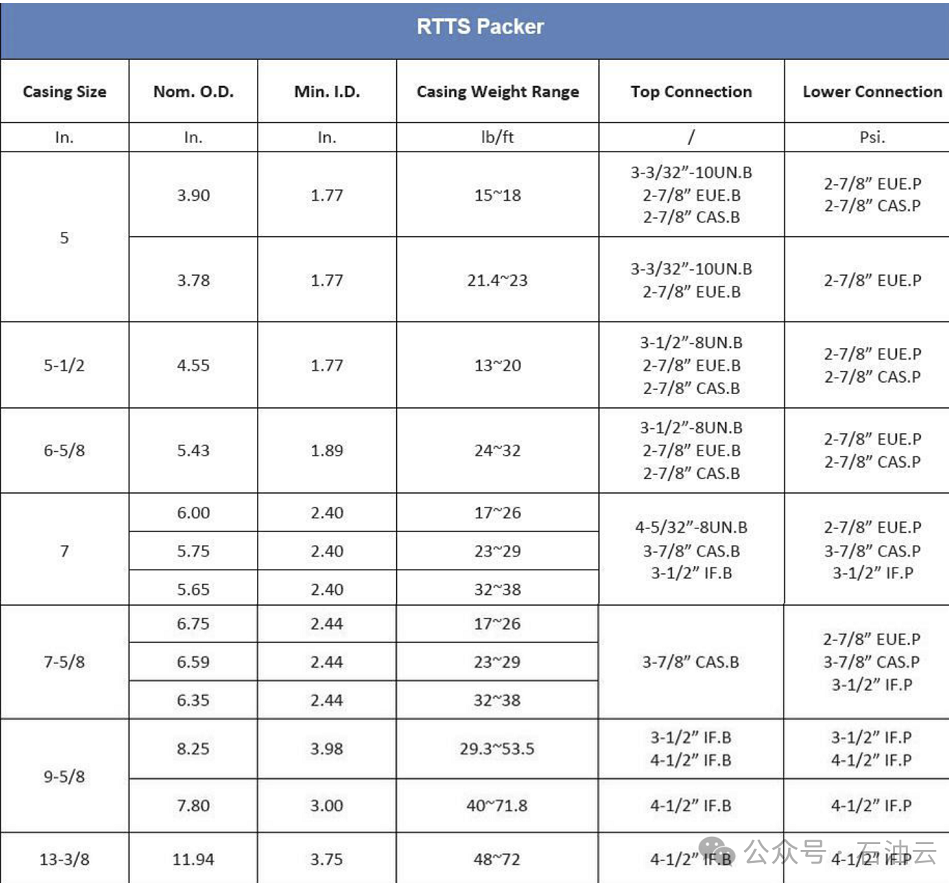

RTTS packers come in various sizes, including 4 1/2 inches, 5 inches, 5 1/2 inches, 7 inches, and 9 5/8 inches. Each size of packer is equipped with a J-slot reversing mechanism, mechanical slips, a packer body, and a hydraulic anchoring structure. The hydraulic anchoring structure prevents the packer from being pushed upwards when the pressure below the packer is too high. Because of this hydraulic anchoring function, this tool is particularly suitable for testing underpressured wells.

The model numbers of the packers correspond to their sizes: 4 1/2 inches, 5 inches, 5 1/2 inches, 7 inches, and 9 5/8 inches, making them suitable for downhole operations in different casing sizes.

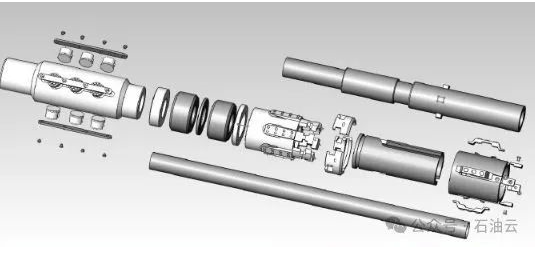

2. Structural Composition:

This packer consists of a hydraulic anchor, a rubber cylinder, a slip, and a guide block.

3. Features:

a) The hydraulic anchor is anchored by tubing pressure, which can effectively prevent displacement of the top of the packer.

b) The slip is separated from the friction block and is compressed in the tapered groove in an unsealed state.

c) The automatic setting J-shaped device is more convenient.

d) The slip-type packer casing coupling with a tungsten carbide alloy block and hydraulic anchoring device makes it easy to install the packer.

4. Operational Considerations

a) Before running the packer downhole, it is necessary to fully run it into the well and flush it to ensure that there are no hard objects in the well that hinder the packer from being lowered and set.

b) The assembly mechanism should operate smoothly and slowly. No emergency stop button should be set to prevent the assembly mechanism from being accidentally operated and locked.

c) The installation position should avoid the coupling of the machine housing.

d) If no jamming is encountered during the unsealing process, the standpipe needs to be pulled out again until it reaches the well depth so that the alloy block embedded in the casing can be taken out from the casing and lifted.

5. Advantages of RTTS Packers

1.RTTS packers are the most commonly used tools for oil well testing. They are especially suitable for low-pressure, low-permeability wells and heavy oil wells (non-self-spraying wells), and for situations where serious contamination occurs during drilling, cementing, and other construction processes. Due to the large amount of loss, a large number of test wells are required, and multiple flowbacks are needed to obtain true fluid and formation parameters.

2.RTTS fracturing tools can achieve bidirectional testing of TCP (Conventional Fracturing) + MFE (Multi-stage Fracturing), and can also implement triple testing of TCP (Conventional Fracturing) + MFE (Multi-stage Fracturing) + JET (hydraulic pump drainage), and then realize TCP (Conventional Fracturing) + MFE (Multi-stage Fracturing) + JET (hydraulic pump drainage) + acidizing and other four combined testing new technology.

3.RTTS packer tools are easy to operate, cost-effective, can greatly reduce costs, and have good economic and social benefits.

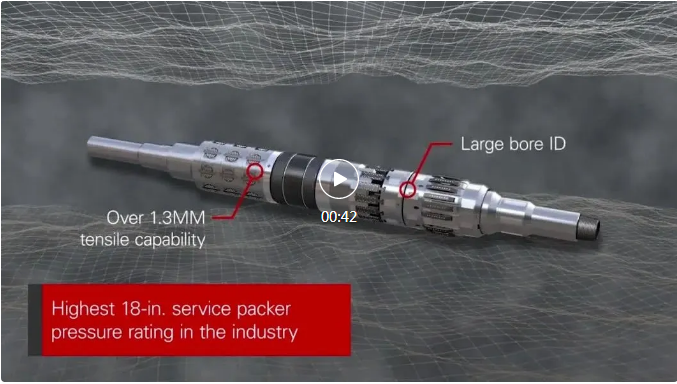

RTTS (Retrievable Test-Treat-Squeeze) packers are full-opening, retrievable packers used for testing, treating, and cementing operations. In most cases, this tool is run downhole with a circulating valve assembly. The packer body includes a J-slot mechanism, mechanical slips, a packer element, and a hydraulic slip. The large, heavy-duty slips in the hydraulic locking mechanism help prevent the tool from being pumped into the well. For packer bodies ≤ 3 1/2 inches (88.9 mm), a drag spring operates the J-slot mechanism, while for packer sizes ≥ 4 inches (101.6 mm), a drag block is used. All packer bodies come standard with an automatic J-slot sleeve. If a circulating valve is used, it is of the locking open/locking closed type, which can be used as both a circulating valve and a bypass valve. When the packer is set, the valve automatically locks in the closed position. During testing or cementing operations, the locking device prevents the valve from being pumped open. The straight J-slot in the locking open position matches the straight J-slot (optional) in the packer body. This combination eliminates the need to rotate the tubing to close the circulating valve or reset the packer after the tubing has been displaced 1 by cement.

Features:

- The full-opening design of the packer mandrel bore allows large volumes of fluid to be pumped through the tool. Tubing-conveyed perforating guns and other wireline tools can be run through the packer.

- The packer can be set and repositioned multiple times through simple tubing manipulation.

- Tungsten carbide inserts provide greater holding power and better wear resistance, which is especially effective when used in high-strength casing. Pressure applied through the tubing activates the inserts in the hydraulic locking mechanism

4.The optional integrated circulating valve locks in the open or closed position during squeeze testing operations and is easily opened when needed to allow circulation above the packer.

Operation:

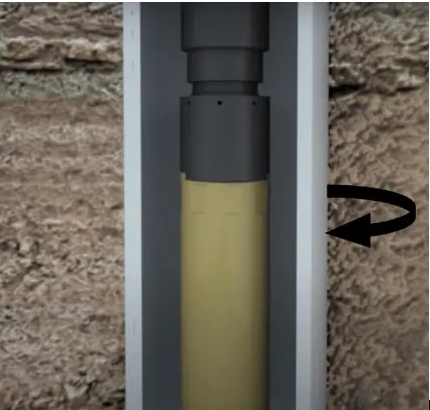

To set the packer, the tool is lowered slightly below the desired setting location and then lifted and rotated several turns. If the tool is at the bottom, it may only be necessary to turn it half a turn. However, in deep or deviated wells, several rotations using a rotary tool may be required. To maintain position, right-hand torque must be maintained until the mechanical inserts on the tool are set and can begin to bear weight. Balanced pressure must be applied to both sides of the packer to release the packer. When pulling out of the tubing, the circulating valve remains closed, creating reverse circulation at the bottom of the packer. When the tubing is lowered, rotated to the right, and lifted, the circulating valve opens to allow fluid to be circulated out of the well.

How to Set and Release an RTTS Packer

Before running the packer downhole, move the friction block sleeve up and down several times to check the mobility of the mechanical slips, and then run it into the well.

When preparing to run into the well, lock the circulating valve in the open position; the J-slot is also in the locked position, that is, the lug on the J-slot hook point, and the slip is in the retracted state.

During the running process, the slip mechanism slides upward, setting the mechanical slips and closing the circulating valve. To prevent accidental closure of the valve, lower the tubing string and rotate it to the right, lift it to the open position, and then rotate it to the left to the open locked position, being careful not to unscrew the tubing string.

When the tool reaches the test position where operations are to be performed, lower it slightly below the setting position, and then lift it to the setting position.

Downhole, rotate the tubing string several turns to the right, rotating the tool only 1/2 turn.

Maintain right-hand torque on the tubing string and apply weight to the mechanical slips. Stop lowering the tubing string, rotate it to the left, and release the right-hand torque. Typically, 1/2 turn of rotation every 300 meters is sufficient, and it should not exceed the number of right-hand rotations during setting.

Stop lowering the tubing string, rotate it to the left, and release the right-hand torque. Typically, 1/2 turn of rotation every 300 meters is sufficient, and it should not exceed the number of right-hand rotations during setting.

While applying right-hand torque, lower the tubing string onto the packer, placing the tool in the desired setting force working state.

Open the circulating valve and maintain fluid, rotate the tubing string to the right, and then lift it; apply pressure to the tubing and continue lifting until circulation occurs. Now hold in this position, inject fluid, and then release the tubing string until the fluid pressure ends, allowing the tool to begin bearing weight. Rotate to the left and release torque, then continue lowering weight until the packer is set again with the desired .

When finishing testing and releasing the packer, first balance the pressure on the packer. Then, lift the tubing string without rotating it, thus keeping the circulating valve in the closed position and establishing reverse circulation around the packer.

When finishing testing and releasing the packer, first balance the pressure on the packer. Then, lift the tubing string without rotating it, thus keeping the circulating valve in the closed position and establishing reverse circulation around the packer.

Lower the tubing, rotate the tubing string, and then lift it, thereby opening the circulating valve, and the tool can then be pulled out of the wellhead.

Post time: Feb-25-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141