The term “lost weight on bit” (LWB) refers to a scenario during drilling where the designed weight on bit (WOB) fails to act on the drill bit. Instead, due to excessive friction between the downhole drill string and the wellbore wall, all the applied weight is absorbed by the drill string.

When applying WOB, wellbore shrinkage often causes the weight to be fully exerted on the drill string or stabilizers. This requires continuous weight application, but the compressive strength of the drill string must be taken into account. Each weight increment may result in a small downward movement of the drill string; repeated weight application allows the drill string to move past the shrunken wellbore section. At the moment the drill string exits this section, the drill bit quickly contacts the wellbore bottom. Since the WOB at this point is higher than that for normal drilling, the bit penetrates the formation more deeply, leading to a sudden increase in torque. This may cause the rotary table or top drive to stall. If stalling occurs, do not lift the drill string abruptly—release the torque first. Normal drilling can be resumed after repeated adjustments.

Lost weight on bit typically occurs in the following cases: directional drilling of vertical wells with back-reaming or directional wells with multiple back-reaming operations, window milling and sidetracking directional drilling, and horizontal well directional drilling. Due to wellbore trajectory and various resistance factors, it is difficult for the pressure applied to the drill string to transmit to the drill bit. From comprehensive mud logging instruments and weight indicators, this is shown as: the drill bit position remains unchanged and no footage is gained despite continuous WOB increase; pump pressure does not rise and no pump blocking happens. However, further WOB increase may lead to sudden pump blocking. For directional wells, lost weight on bit not only disrupts normal directional operations but also risks stuck pipe if operations are improper.

1.Strengthen Wellbore Trajectory Control and Optimize Drill String Configuration

1.Strengthen Wellbore Trajectory Control and Optimize Drill String Configuration

To address lost weight on bit caused by poor wellbore trajectory, the main engineering measure is to enhance trajectory control. For high-angle and extended-reach directional wells, full-well guided control should be adopted to keep the well deviation and azimuth in line with the design, avoiding back-reaming due to deviations from the design.

For lost weight on bit resulting from poor wellbore trajectory, the most effective solution is to simplify the drill string configuration: reduce the number of drill collars and increase the number of heavy weight drill pipes (HWDP). This lowers the rigidity of the drill string, reduces the contact area between the drill string and the mud cake, and prevents both lost weight on bit and differential sticking.

For lost weight on bit in horizontal wells, measures should focus on wellbore cleaning, lubrication, and driller’s operational techniques.

2.Enhance Cleaning

Enhancing cleaning includes wellbore cleaning and surface mud purification using surface solid control equipment.

Improve the Cuttings-Carrying Capacity of Mud

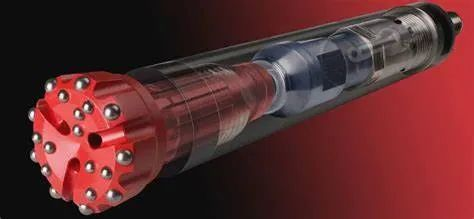

In recent directional drilling projects, PDC bits combined with steerable motor technology are commonly used, which achieve relatively fast footage and grind cuttings into fine particles—posing certain challenges to wellbore cleaning.

Displacement Requirements for Different Wellbore Sections: For the φ311 mm well section, the displacement must be higher than 3.4 m³/min; for the φ216 mm well section, it must be higher than 1.1 m³/min.

Adjust Mud Rheological Parameters Based on Downhole Cuttings Return: For low-solids polymer drilling fluid, the dynamic plastic ratio should be controlled between 0.42 and 0.50 to ensure good cuttings-carrying effect. Regarding mud viscosity and gel strength, the viscosity of high-angle directional wells should be maintained above 48 seconds—high viscosity and gel strength help prevent vertical settlement of cuttings.

In one drilling project, when the well deviation was 50–60 degrees, the addition of organic positive gel reduced the mud viscosity to approximately 42 seconds, leading to poor downhole cuttings return and lost weight on bit during directional drilling. Normal downhole conditions were restored after increasing the mud viscosity to 50 seconds.

For wells with a depth exceeding 200–300 meters, horizontal wells can be pulled to the well section with a deviation of 20–30 degrees. In the drill string configuration for directional drilling, several stands of drill collars are usually included. In newly drilled wellbores, the presence of drill collars increases the annular mud return velocity, so cuttings beds usually settle in the old wellbore. Therefore, some drilling crews only pull the newly drilled well section, which has little effect on breaking up cuttings beds.

3.Improve Mud Lubricity and Mud Cake Quality

Enhance Mud Lubricity

Specific measures to improve mud lubricity include, first, increasing the dosage of lubricants and, second, using a combination of different lubricants.

In directional drilling, crude oil is usually mixed into the mud during directional operations. Although crude oil has good lubricity, its addition degrades mud cake quality. Therefore, in directional drilling operations, crude oil should be used in conjunction with water-based lubricants. This not only solves the lubrication problem but also avoids thick mud cakes caused by excessive crude oil dosage.

Sliding friction increases with the friction coefficient. To address this, approximately 3–5 tons of crude oil can be mixed into the mud, with the crude oil content not exceeding 9–10%.

Improve Mud Cake Quality

To improve mud cake quality, mud materials such as sulfonated asphalt and phenolic resin can be added. High-quality mud cake reduces the risk of differential sticking caused by lost weight on bit.

In addition to liquid lubricants, solid lubricants and extreme pressure lubricants are also effective in reducing lost weight on bit. When lost weight on bit occurs during directional drilling in hard formations, adding 200–300 kg of expanded graphite at one time has a good effect on resolving lost weight on bit caused by poor lubricity.

Contact :May Ye

Mobile/Whatsapp:+0086-18109206861

Email: landrill@landrilltools.com

Web: www.landrilltools.com

Post time: Sep-28-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141