Details determine success or failure, especially in the drilling industry. Oil drilling is a high-risk and complex operation, and every operational procedure is crucial to the safety and success of the entire drilling work. As key technical personnel on the drilling site, drillers’ operational standardization and technical proficiency directly affect operational efficiency and accident rates.

- What are the main functions of well control equipment?

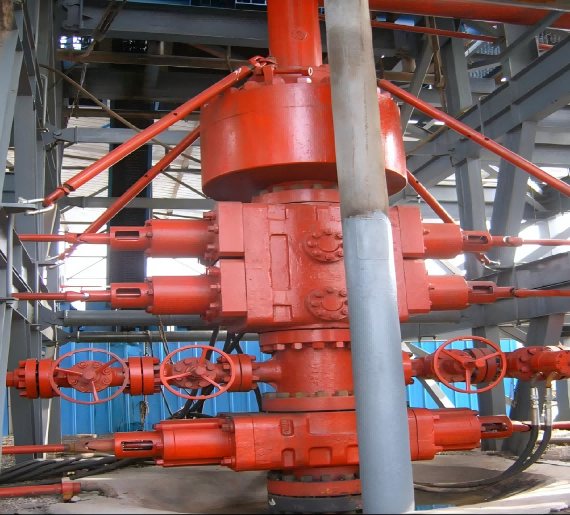

(1) Prevent blowouts: Maintain the static fluid column pressure of drilling fluid in the wellbore slightly higher than the formation pressure to avoid blowout conditions.

(2) Detect kicks in a timely manner: Monitor oil and gas wells to identify blowout signs early and take control measures promptly.

(3) Rapidly control blowouts: After a kick, well kick, or blowout occurs, shut in the well quickly, implement kill operations, and re-establish pressure control over the oil and gas well.

(4) Handle complex situations: Perform fire fighting and emergency rescue operations when the oil and gas well is out of control.

2.What are the functions of the choke manifold?

(1) Implement kill operations through the throttling effect of the choke valve to displace contaminated drilling fluid in the well, while controlling wellhead casing pressure and standpipe pressure, restoring the pressure control of the drilling fluid column on the bottom hole, and stopping the kick.

(2) Reduce wellhead pressure through the pressure relief function of the choke valve to achieve “soft shut-in”.

(3) Reduce wellhead casing pressure through the large discharge function of the blowout prevention valve to protect the wellhead BOP stack.

3.Why should the well be shut in quickly when a kick is detected?

(1) Control the wellhead to facilitate safe well pressure control.

(2) Stop the continuous entry of formation fluids into the wellbore.

(3) Maintain a sufficient amount of drilling fluid in the wellbore to reduce the casing pressure during well shutdown and kill operations.

(4) Accurately calculate the formation pressure and drilling fluid density.According to AQ 2083-2025, the response time of the well control system is required to be ≤15 seconds (intelligent well shutdown), and multi-parameter monitoring is required (alarm triggered when flow difference ≥10% or pit volume change ≥2m³).

4.Which positions should be inspected when the temperature of the drilling pump bearing is too high?

(1) Check if the lubricating oil holes of the bearing are blocked to ensure unobstructed lubrication channels;

(2) Inspect if the lubricating oil is clean, sufficient, and if the oil quality is deteriorated or contaminated;

(3) Check if the bearing itself is damaged, stuck, or severely worn. In addition, inspect if the bearing installation is too tight or loose, if the coaxiality deviation is excessive, if the equipment load and rotational speed exceed the standard, and if the heat dissipation conditions are good.

Details determine the success or failure of drilling operations. Every operation must strictly comply with procedures and be performed in a standardized manner to eliminate operational errors of “cutting a step”, and jointly ensure the safe and efficient conduct of drilling operations.

Post time: Oct-22-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141