1 High – Temperature Resistant Equal – Wall Thickness Screw Drilling Speed – Increasing Technology

The high – temperature resistant equal – wall thickness screw is a speed – increasing tool specially designed to meet the needs of high performance and high reliability in the drilling industry. During the use of traditional drilling screws, due to the high – temperature environment and complex working conditions, severe wear and fatigue damage often occur, leading to a decrease in drilling efficiency. However, the high – temperature resistant equal – wall thickness screw has excellent high – temperature resistance, which can maintain stable mechanical properties in a high – temperature environment, reduce equipment failures caused by high temperatures, and thus improve drilling speed.

1.1 Technical Principle

The downhole motor directly drives the drill bit to break rock and drill, which can more efficiently transmit power to the drill bit, reduce energy loss, and optimize the working performance of downhole tools. This is because the motor directly drives the drill bit, which can avoid power loss caused by the loss of the transmission system, so that more energy is used for rock – breaking drilling, improving drilling speed and efficiency. To further improve the high – temperature resistance of the equipment, the high – temperature resistant equal – wall thickness screw adopts some special high – temperature resistant materials and surface treatment technologies. For example, high – alloy steel is used as the main material, or the equipment surface is subjected to heat treatment or coating treatment to improve the high – temperature resistance of the equipment. Since the stator adopts a pre – fabricated steel shell with a specific cross – section shape, and then is injected with glue to form a thin and equal – thickness rubber layer, the motor has a larger torque output and can adapt to various complex geological conditions. This structure makes the gap between the stator and the rotor of the motor smaller, thereby reducing friction and wear, and improving the service life and reliability of the equipment. The tool also adopts a mechanical locking or friction – reducing mechanism to improve the rotation accuracy and stability of the equipment, and avoid the decrease in drilling efficiency caused by screw vibration or eccentricity.

1.2 Adaptability Analysis

In terms of performance, the high – temperature resistant equal – wall thickness screw drilling tool not only has all the characteristics of ordinary screw motors, but also has the characteristics of large torque, easy start – up, and strong overload resistance, making it more suitable for drilling operations in deep high – temperature formations. By using a straight screw with a small pendulum drilling tool in high – dip formations, high drilling speed can be achieved with low drilling pressure, and a significant effect of reducing and preventing deviation can be achieved. At the same time, the design of the straight screw can also provide stable support force to prevent the drill bit from deviating in high – dip formations, thereby improving the stability of drilling. Both theoretical research and on – site applications show that the fast drilling technology using high – temperature resistant equal – wall thickness screws can significantly increase the rotational speed of the drill bit at the bottom of the well, adapt to the downhole high – temperature environment, and effectively optimize the wellbore quality control. At the same time, it can also reduce the top drive load and drilling tool torque, and extend the service life of the drilling tool. Compared with the conventional PDC drilling tool assembly, this method can greatly improve drilling efficiency and show excellent comprehensive economic and technical effects.

2 Turbine + Impregnated Diamond Bit Speed – Increasing Technology

The turbodrill is a downhole power tool that can convert the hydraulic energy of the fluid into rotational mechanical energy, thereby driving the drill bit to rotate and impact, and realizing high – speed and efficient drilling. It is mainly composed of three parts: the turbine section, the universal shaft, and the transmission shaft. The impregnated diamond bit is a type of diamond bit. Its matrix is made by sintering diamond polycrystalline particles on the outside of the matrix, which makes the bit more aggressive. The matrix has a certain height, its outer diameter is slightly larger than the outer diameter of the bit body, and its inner diameter is slightly smaller than the inner diameter of the bit body. The outer side, inner side, and bottom of the matrix are all provided with water grooves to discharge rock cuttings and cool the bit through the flushing fluid. The matrix has sufficient compressive and impact strength, as well as high hardness and wear resistance. The turbodrill and the impregnated diamond bit are important tools in the oil drilling process, and their combined use can jointly improve drilling efficiency and drilling quality.

2.1 Technical Principle

The turbine section is the core component of the turbodrill, which is composed of turbine stators and rotors, centralizing bearings, main shafts, and casings. It can convert the fluid energy of the drilling fluid into the mechanical energy of the main shaft rotation. Its internal structure includes multiple stages of paired stators and rotors. When the drilling fluid enters the stator along the drilling tool, the stator will guide the drilling fluid to have a certain direction and speed, and then enter the rotor. In the rotor, the drilling fluid will impact the blades to generate a certain pressure difference, which will cause the rotor to rotate. Through this mechanism, the energy of the drilling fluid is converted into mechanical energy that drives the turbine shaft to rotate.

The main rock – breaking method of the impregnated diamond bit is abrasive rock breaking, that is, using diamond particles to continuously grind, scratch, and abrade the rock under the action of axial force and torque, so as to achieve the purpose of breaking the rock. The diamond bit mainly using this rock – breaking method has high wear resistance, which can effectively deal with the highly abrasive rocks in hard – extremely hard abrasive formations, and improve the drilling efficiency and the service life of the drill bit.

2.2 Adaptability Analysis

The turbodrill + impregnated diamond bit adopts an all – metal structure, which has higher high – temperature resistance and more stable drilling effect, enabling it to work stably even in extreme environments. This is particularly important in drilling operations of deep wells and ultra – deep wells. This tool combination has excellent axial balance performance, which can reduce lateral vibration, generate a smooth wellbore trajectory, reduce damage to the well wall, thereby protecting the drill bit and other downhole tools, and is beneficial to subsequent operations. Due to the high – speed rotation characteristics of the turbodrill, the combination of the impregnated diamond bit and the high – speed turbine can exert extremely high drilling efficiency in deep formations with high hardness and strong abrasiveness, and greatly improve the drilling capacity.

3 Torque Impactor Drilling Speed – Increasing Technology

The torque impactor is a pure mechanical power tool mainly used for auxiliary rock breaking of PDC bits. The tool generates a pressure drop through a variable – flow nozzle, forming a high – pressure zone and a low – pressure zone inside it. When the pressure difference acts on the tool, the flow channel switches to make the impact hammer and the starting hammer inside the tool reverse at high speed. The impact hammer continuously impacts the impact surface, thereby transmitting the impact force to the drill bit, forming a high – frequency pulse torque. It cleverly converts the fluid energy of the drilling fluid into torsional, high – frequency, uniform, and stable mechanical impact energy and directly transmits it to the PDC bit, keeping the drill bit and the bottom of the well continuous at all times.

3.1 Technical Principle

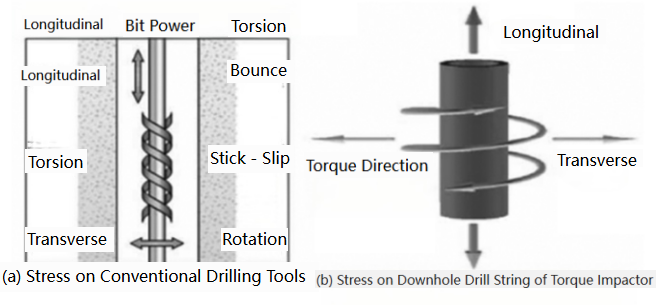

The high – frequency stable impact force of 750 times/min to 1500 times/min provided by the torque impactor is equivalent to cutting the formation multiple times per minute. This enables the drill bit to cut the formation without waiting for the torsion to accumulate sufficient energy, completely changing the operation state of the drill bit. At this time, the drill bit has two forces for cutting the formation: one is the torque provided by the rotary table, and the other is the impact force provided by the torque impactor. These two forces are directly transmitted to the drill bit itself, so that the torque transmitted by the drill pipe can be fully used for cutting the formation without waste. The combined action of this torque and impact force can not only significantly improve the drilling speed, but also effectively reduce or eliminate the harmful vibration of the drill bit during drilling in hard formations, protect the drill bit, extend the service life of the drill bit, and at the same time reduce the fatigue strength of other drilling tools and extend the service life of other drilling tools. Figure 1 shows the stress state of the downhole drill string of the conventional drilling tool and the torque impactor.

3.2 Adaptability Analysis

As an advanced drilling tool, the torque impactor has a reasonable internal mechanical structure, no rubber parts and electronic components, and few parts. Even if it fails, it is only equivalent to a drill bit sub rotating continuously together with the PDC bit without affecting the continuous drilling, and there is no need to trip the drill, so it has high reliability. The torque impactor is suitable for various complex formations, especially the igneous rock formations with strong abrasiveness and poor drillability. At the same time, the tool is easy to operate. When using the torque impactor, it only needs to be directly connected to the rotating or directional drilling tool, which is simple and convenient to operate.

4 Compound Impactor

The compound impactor is an advanced drilling equipment with an energy conversion device designed inside, which can convert the fluid energy of the drilling fluid into pulse impact energy, thereby generating stable high – frequency circumferential and axial impact forces. This working method significantly improves the rock – breaking efficiency of the drill bit, effectively solves the problems of stick – slip and pressure holding during drilling, and thus achieves the goal of speed increase. The compound impactor not only has the torsional impact characteristics and advantages of the torque impactor, but also innovatively combines the axial impact function.

compound impactor

4.1 Technical Principle

The internal structure of the compound impactor is composed of pure metal machinery. It converts the fluid energy of the drilling fluid into high – frequency and stable circumferential and axial impact energy through a reversing mechanism. During the drilling process of the conventional drilling tool assembly, after the PDC bit enters the formation, the energy accumulation of the upper drilling tool needs to exceed a certain critical value to start shear rock breaking. In contrast, the compound impactor converts the fluid energy of the drilling fluid into impact energy, providing high – frequency and stable impact force for the drill bit. In this way, the rock – breaking stress can quickly reach the critical stress for formation shearing, greatly improving the shearing efficiency of the PDC bit . At the same time, due to the reduction in the fluctuation of rock – breaking stress and torque, it is beneficial for the drill bit to perform uniform cutting at the bottom of the well, eliminating the instantaneous extremely high stress on the PDC bit under conventional drilling tools. Therefore, the stress on the drill bit becomes more uniform and stable, thereby extending the service life of the PDC bit and increasing the working footage of a single drill bit.

4.2 Adaptability Analysis

Compared with the torque impactor, the compound impactor increases the energy of longitudinal impact. Theoretically, its rock – breaking efficiency is higher, and it is more suitable for use in tight formations. Under the same size, the optimal drilling pressure of the compound impactor is slightly higher than that of the torque impactor. For the compound impactor, the drill bit used should have stronger impact resistance, and there are shock – absorbing teeth distributed beside the main cutting teeth of the drill bit, which effectively protects the drill bit. When drilling in hard formations and highly abrasive formations, selecting HPM series PDC bits can achieve a perfect balance between drilling speed and footage.

5 Conclusions and Prospects

This article studies and introduces common drilling speed – increasing tools. Through the analysis of the principles, characteristics, and application scopes of these tools, the results show that different types of drilling speed – increasing tools are suitable for different geological conditions and drilling requirements. At the same time, due to the different use costs of various tools, the selection of drilling speed – increasing tools also needs to be considered from an economic perspective.

For future research, it is suggested to carry out from the following aspects: further study the working mechanism of drilling speed – increasing tools, optimize the tool design, and improve their adaptability and efficiency; combine technologies such as artificial intelligence and big data to realize the intelligence and remote monitoring of drilling speed – increasing tools, and improve the safety and efficiency of drilling operations; expand the application of drilling speed – increasing tools in other fields, such as water wells, gas wells, and geothermal wells, to meet the needs of social and economic development.

Contact:Jessie Zhou

Mobile/Whatsapp:+0086-18109206861

Email: landrill@landrilltools.com

Web: www.landrilltools.com

Post time: Oct-16-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141