The drill collar is an indispensable and important component in drilling engineering! The drill collar is primarily located at the bottom of the drill string, used to apply drilling pressure to the drill bit, ensuring necessary strength under compression, while also reducing the vibration, swaying, and bouncing of the drill bit, making the drill bit operate more smoothly. It also has the function of controlling well deviation.

1.Functions of the Drill Collar

1.1 Applying Drilling Pressure: Transmits the drilling pressure from the drill bit to the formation, enabling the drill bit to break the rock.

1.2 Ensuring Strength: Maintains necessary strength under compression to prevent damage to the drilling tools.

1.3 Reducing Vibration: Minimizes the vibration, swaying, and bouncing of the drill bit during the drilling process, improving drilling efficiency.

1.4 Controlling Well Deviation: By properly arranging the drill collars, the trajectory of the wellbore can be controlled, preventing excessive well deviation.

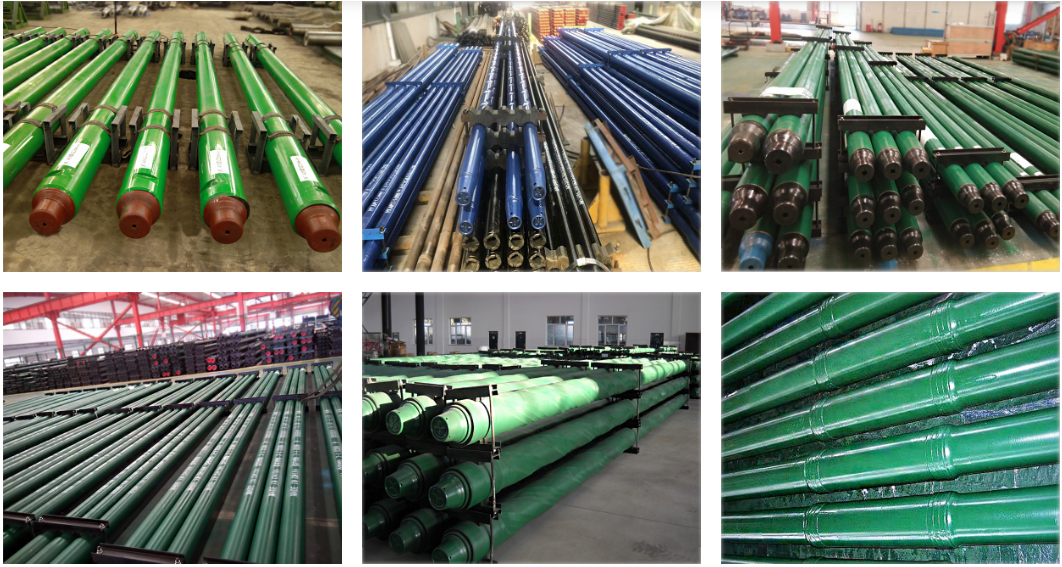

2.Types of Drill Collars

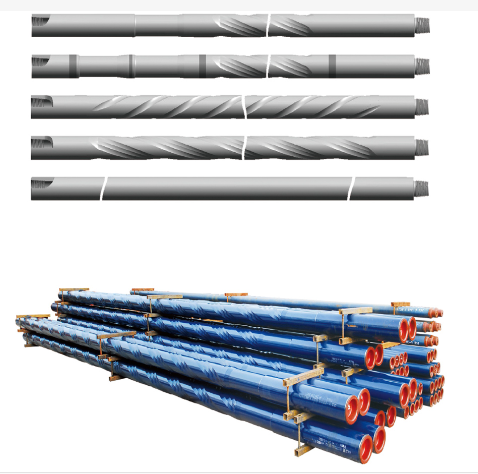

Drill collars come in various shapes, with the most commonly used being round (smooth) drill collars and spiral drill collars. Spiral drill collars have shallow and wide spiral grooves, which reduce the contact area with the wellbore wall, lowering the risk of differential sticking.

3.Specifications of Drill Collars

The API standard drill collar type code consists of two parts. The first part is the NC type thread code, and the second part is a number indicating the outer diameter of the drill collar (in inches). Drill collars have a large wall thickness, typically ranging from 38-63mm, providing significant weight and stiffness.

Junnie Liu

Mobile/Whatsapp:+0086-158 7765 8727

Email: landrill@landrilltools.com

Post time: Mar-17-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141