The cornerstone of load-bearing and pressure conversion hub for the entire wellhead equipment—the casing head. Today, we focus on this crucial component to uncover how this “lifeblood connecting the surface to the subsurface” ensures absolute safety from the surface to the formation.

I. Definition and Function: The Foundation of the Wellhead

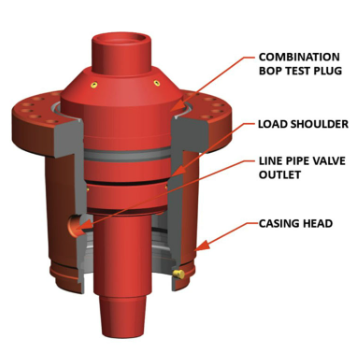

Technically, a casing head is a critical structural component that connects the subsurface casing string to the wellhead equipment. Its lower end is permanently connected to the surface casing via threads, inverted slips, or welding; its upper end is connected to the drilling christmas tree or single (single ram BOP stack) through flanges or clamps.

The core function is to suspend and support the weight of all subsequent technical casings and production casings, providing a mounting base for the entire wellhead equipment. As a wellbore barrier component throughout the drilling, completion, and production lifecycle, the casing head is the foundation for ensuring annular sealing between each layer of casings and achieving pressure isolation and management.

Example Model: TF 20*13 3/8-35MPa

Interpretation: A single-stage flange-type casing head connecting a 508mm (20-inch) casing outer diameter, suspending a 339.7mm (13 3/8-inch) casing outer diameter, with a rated working pressure of 35MPa.

II. Types and Core Components: The Structure of the Lifeblood

Casing heads used on-site are mainly classified into single-stage, double-stage, and multi-stage based on the number of suspended layers. Additionally, there are simple casing heads, commonly used in heavy oil thermal recovery wells in Xinjiang Oilfield, with flanges at the upper end and casing threads at the lower end, mostly adopting mandrel-type casing hangers.

Standard casing heads typically include the body, casing hanger, gate valve, pressure gauge, and set screws. Among these, the casing hanger (commonly known as the “casing slip”) is the key component enabling its core function, used to suspend technical casings or production casings.

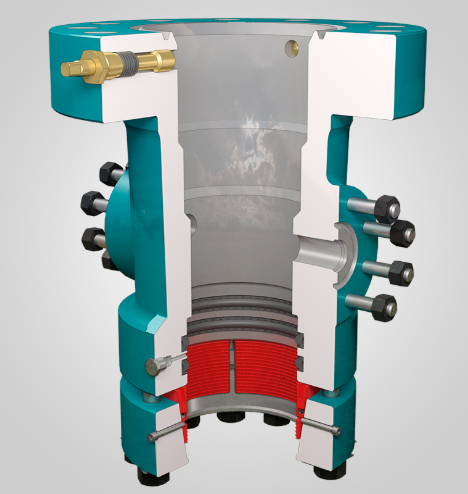

Core sealing is divided into two levels:

- Main Seal: The ability to close the annular space between the suspended casing and the upper casing, serving as the primary barrier against annular pressure.

- Secondary Seal: Static sealing achieved by BT, P, or metal seals between the upper end (neck) of the hanger or between the suspended casing and the casing head body (or drilling-completion integrated christmas tree, special christmas tree) connected to the upper flange. This seal isolates the pressure above the hanger from the annular space below, acting as a crucial and testable supplementary barrier.

III. Key Technical Details: Two Main Suspension and Sealing Methods

1. Mandrel-Type (Threaded) Hanger

Commonly known on-site as the “carrot head”. Its main seal relies on precise calculation of the casing string lowering weight, seated on a precisely machined metal-to-metal conical seal, with a rectangular elastic seal ring as an auxiliary. When the tubing head is installed above it, the BT seal ring in the lower chamber of the tubing head cooperating with the hanger neck can form an effective secondary seal.

Features and Requirements

Advantages: Threaded connection, no need to cut the casing.

Key Requirements: High operational precision—casing setting depth must be accurately calibrated, and sufficient seating weight must be ensured; otherwise, effective sealing cannot be achieved.

2. Slip-Type Hanger

Based on slip shape, they are mainly divided into W-type, WE-type, and WD-type, all connecting through multiple slips engaging with the casing.

WD-Type (Reverse Slips): Exclusive to first-stage (surface) casing heads. Installation does not require calculating the length of the conductor pipe; it only needs to ensure that the ovality and wall thickness of the casing installation position (avoiding the coupling) meet standards, cut and polish the casing to be flat (horizontal degree ≤ 0.5°, outer side polished with a 10° chamfer), then directly sleeve it in. The lower end of the casing head body is designed with two BT seals to achieve sealing with the outer wall of the casing.

W-Type and WE-Type: Both use slip taper and weight to activate rubber seals. The W-type relies on the suspension weight of the casing string to activate the lower seal for primary sealing, with high suspension tonnage and reliable sealing. The WE-type uses manual tightening of upper screws to activate the seal ring, suitable for occasions with low sealing pressure requirements.

IV. On-Site Maintenance Key: Use and Management of Wear Sleeves

During drilling operations, to prevent drill tools from wearing the sealing surface inside the casing head and affecting the final sealing quality, a wear sleeve (extended type adopted in Tarim Oilfield and other places) must be installed during drilling. The wear sleeve is delivered using special tools and fixed and limited by set screws.

Important Inspection Items

After each trip out of the hole, check for eccentric wear of the wear sleeve and confirm that the set screw marks are within the limit slot. If eccentric wear is found, the wellhead must be re-calibrated immediately. Otherwise, long-term eccentric wear may wear through the wear sleeve or even the casing body, causing major well control safety hazards.

In summary, we have systematically reviewed the entire picture of the casing head—the “lifeblood” of the wellhead. With its precision suspension system and multi-level sealing barriers, it supports the weight of the entire well control and production facilities, dividing the annular pressure into ordered levels. As the absolute static foundation for all dynamic controls, the casing head is the cornerstone project for bearing wellhead safety, isolating formation pressure, and achieving wellbore integrity throughout the lifecycle. Strengthening this foundation anchors the most fundamental guarantee for the safety lifecycle of the entire well.

Contact :Jessie Zhou

Mobile/Whatsapp:+0086-18109206861

Email: energy@landrilltools.com

Post time: Dec-30-2025

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China

5-1203 Dahua Digital Industrial Park Tiangu 6th Road,Hi-tech development Zone Xi'an, China  86-13609153141

86-13609153141